MacLean Vehicle Monitoring System (VMS)

Mining operators and internal teams lacked real-time visibility into vehicle health during long underground shifts, relying on delayed and fragmented email-based updates

My Role

Product Designer / UX Researcher

Timeline: 2022–Present

Platform:

Web (B2B, Enterprise, Safety-Critical)

Timeline

2022 - currentProject Overview

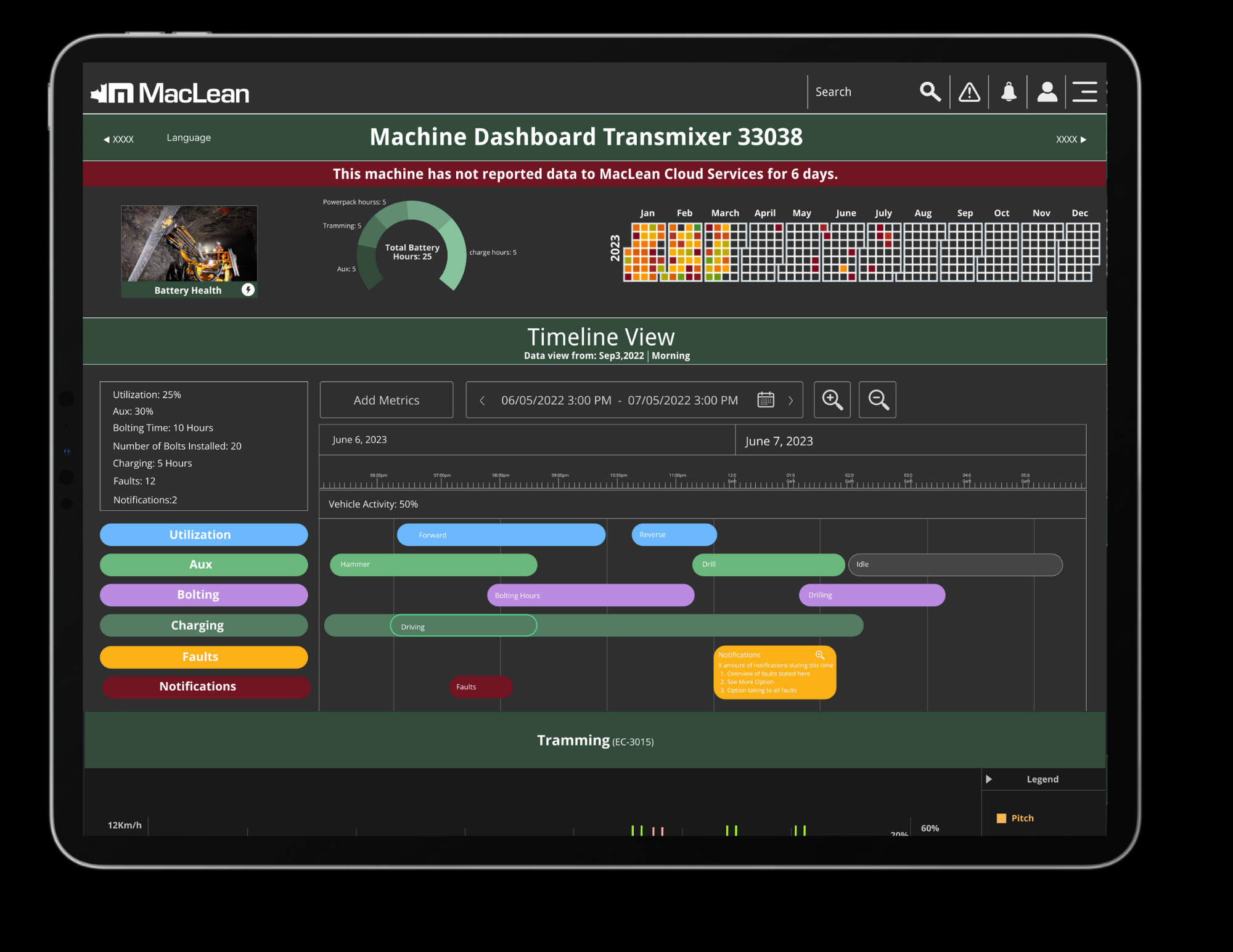

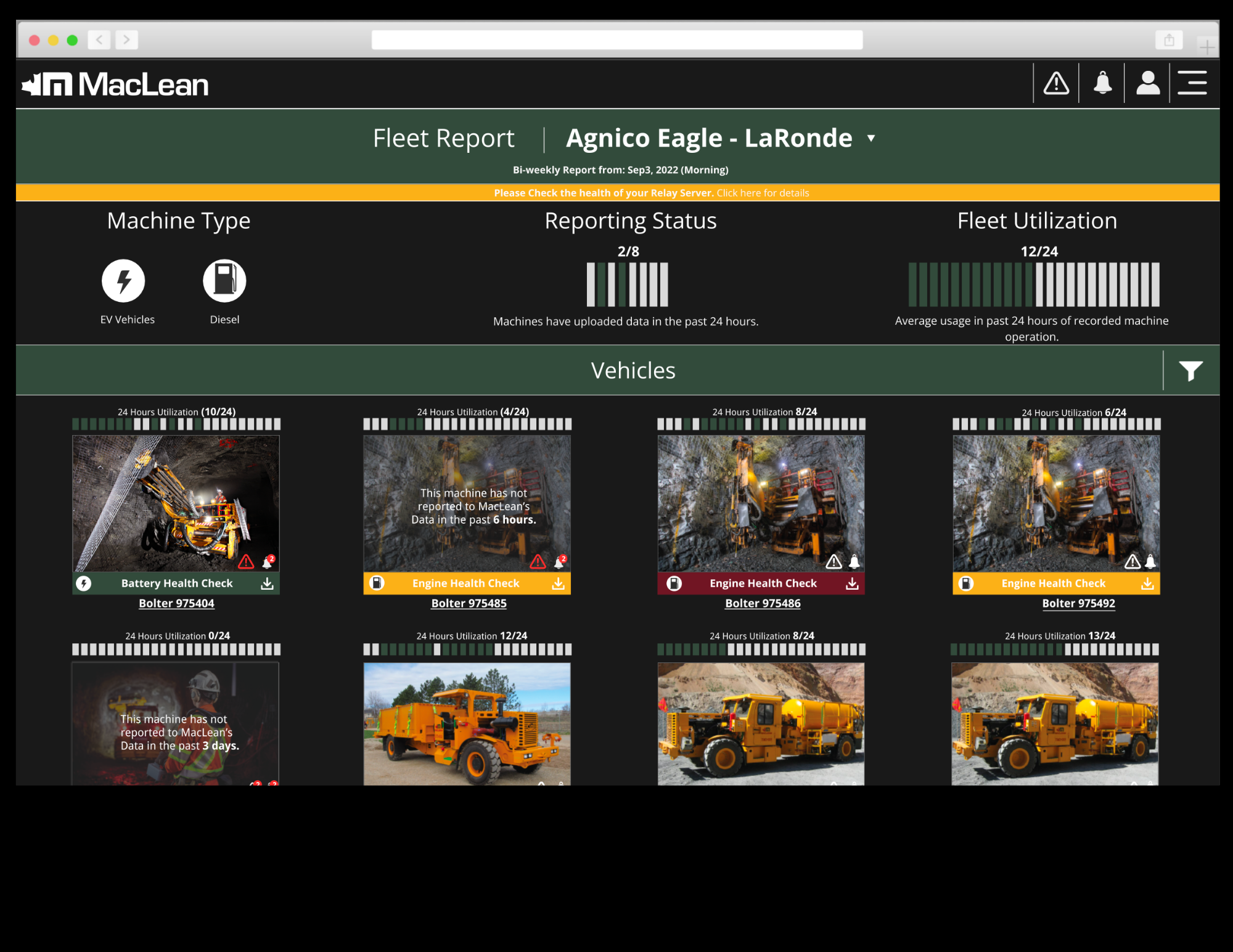

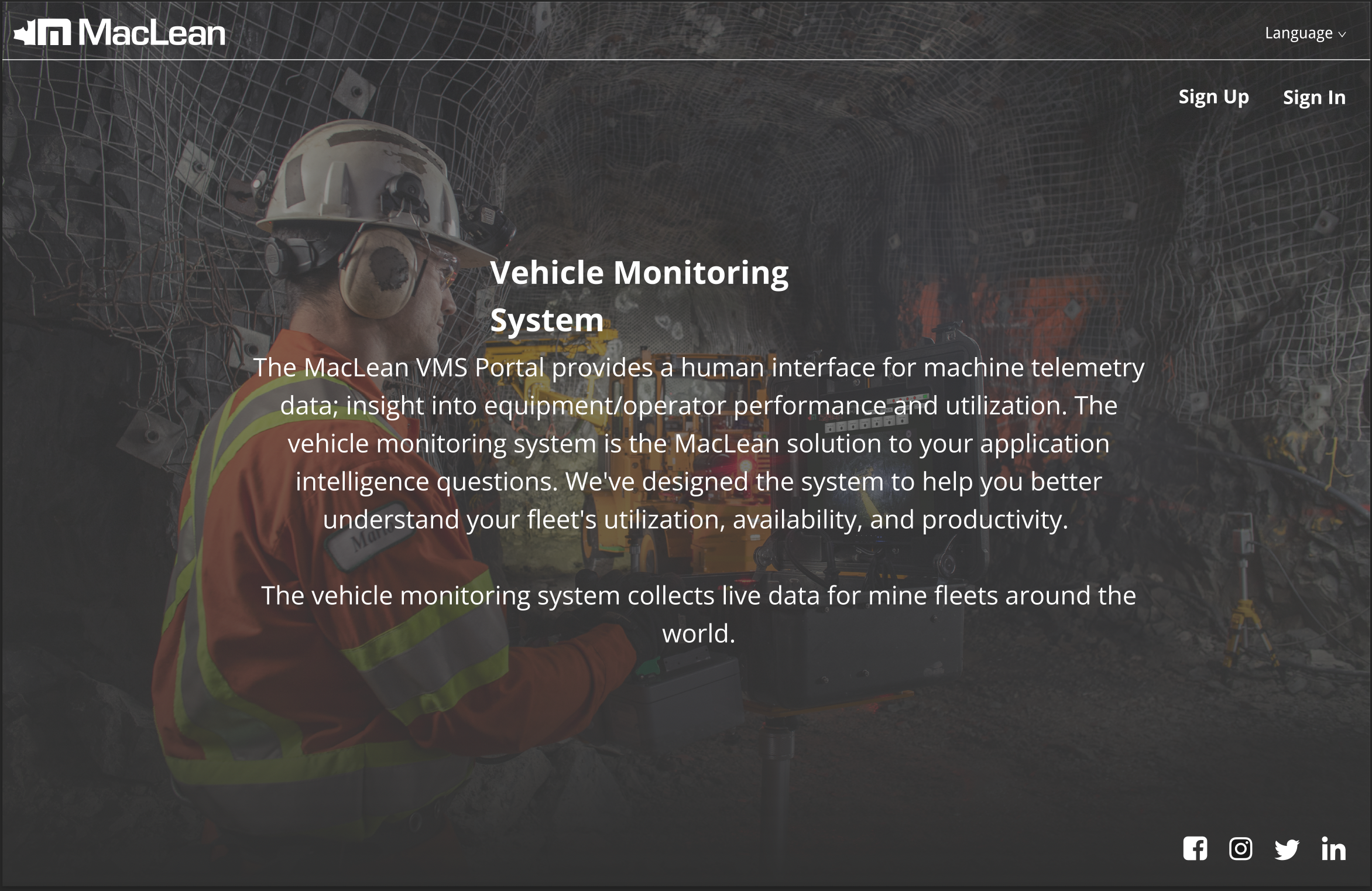

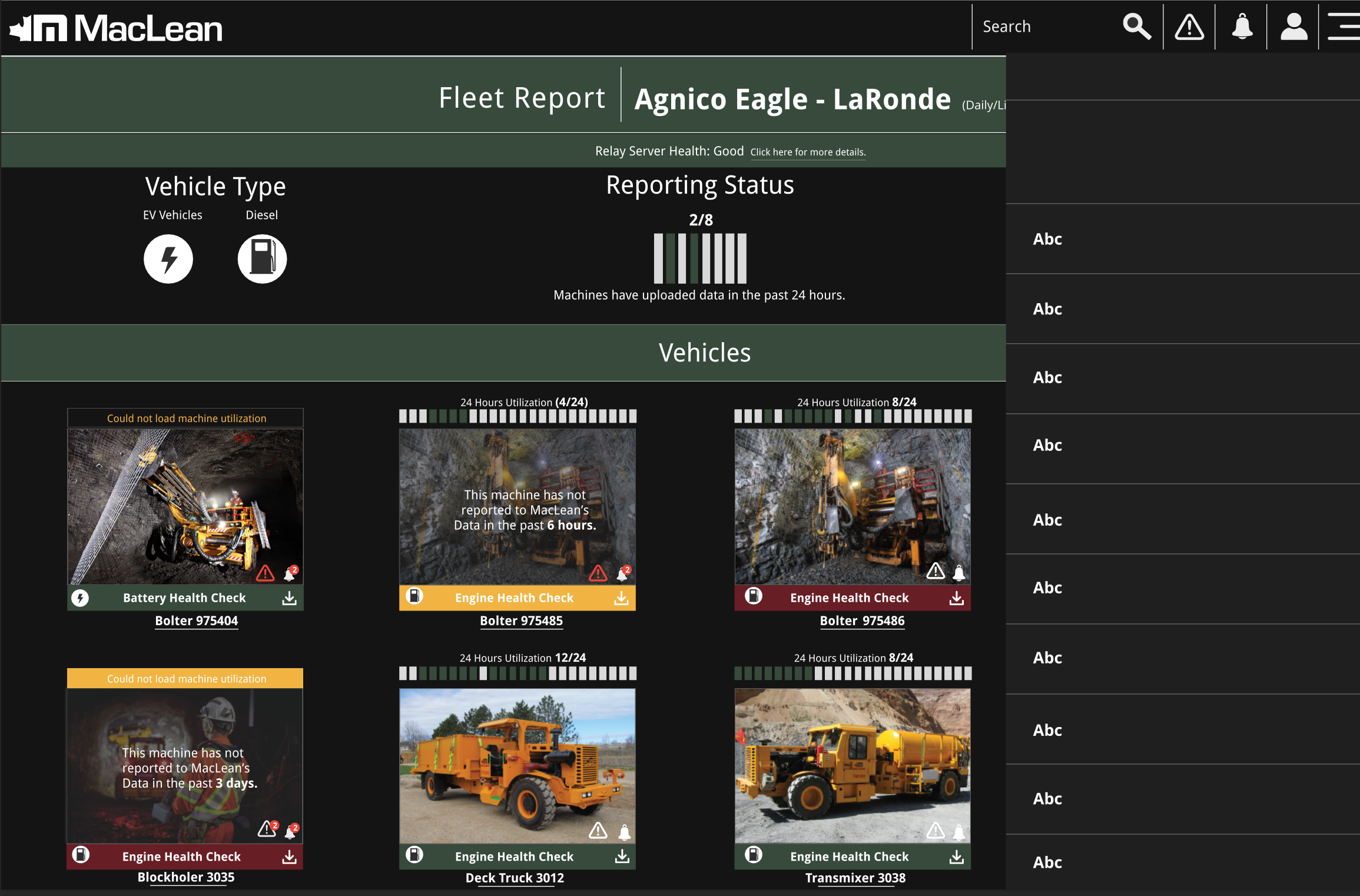

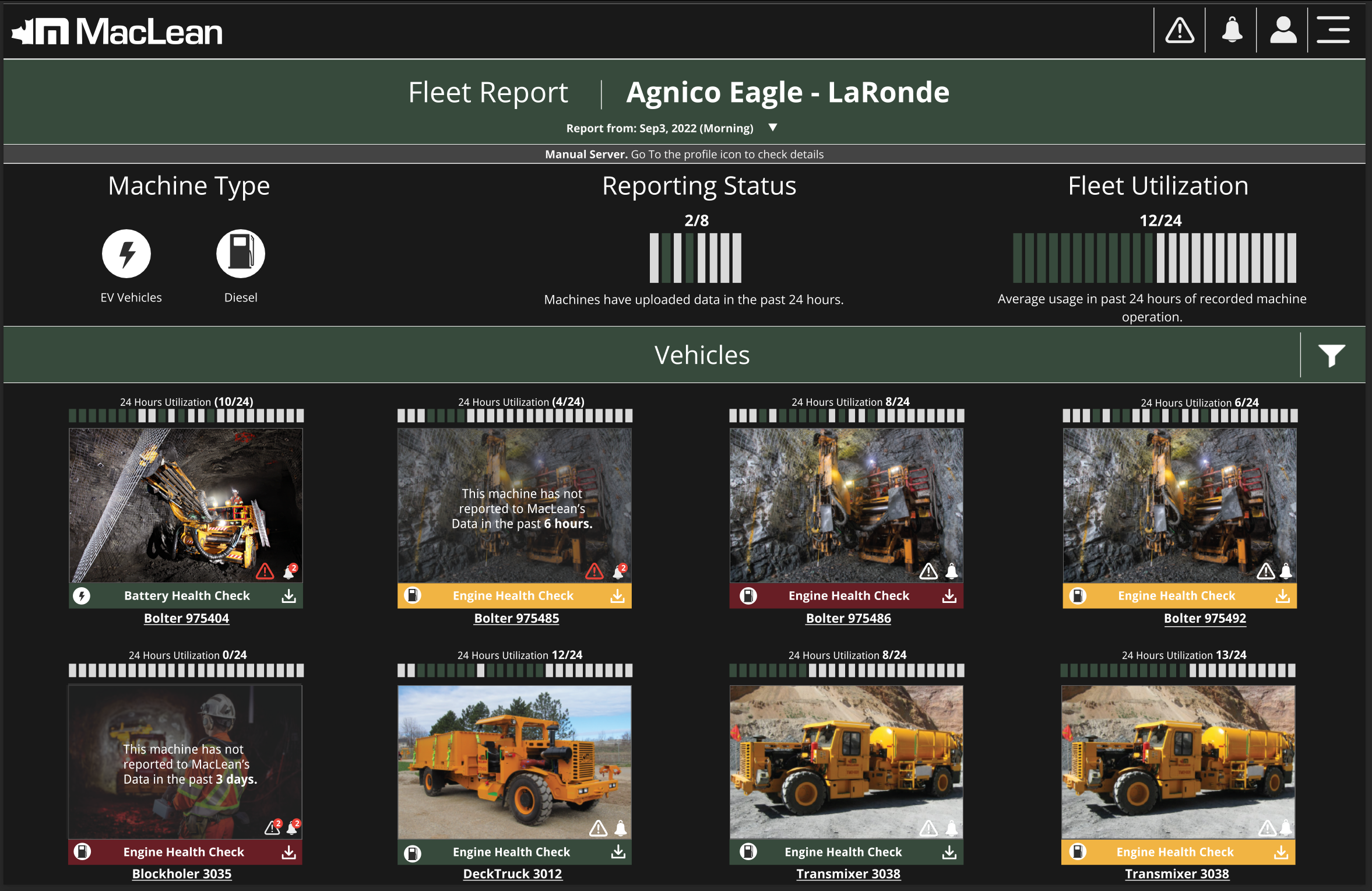

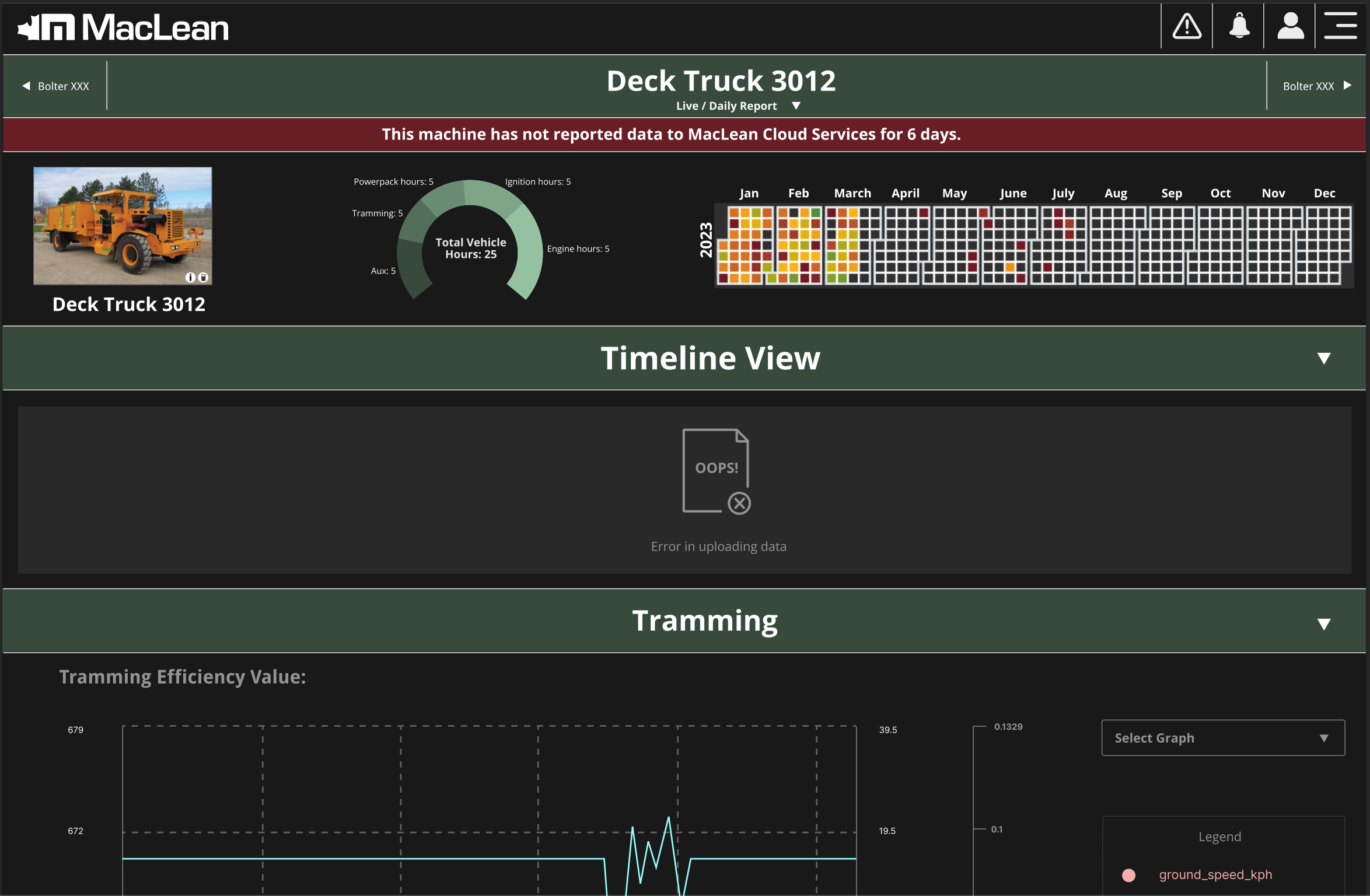

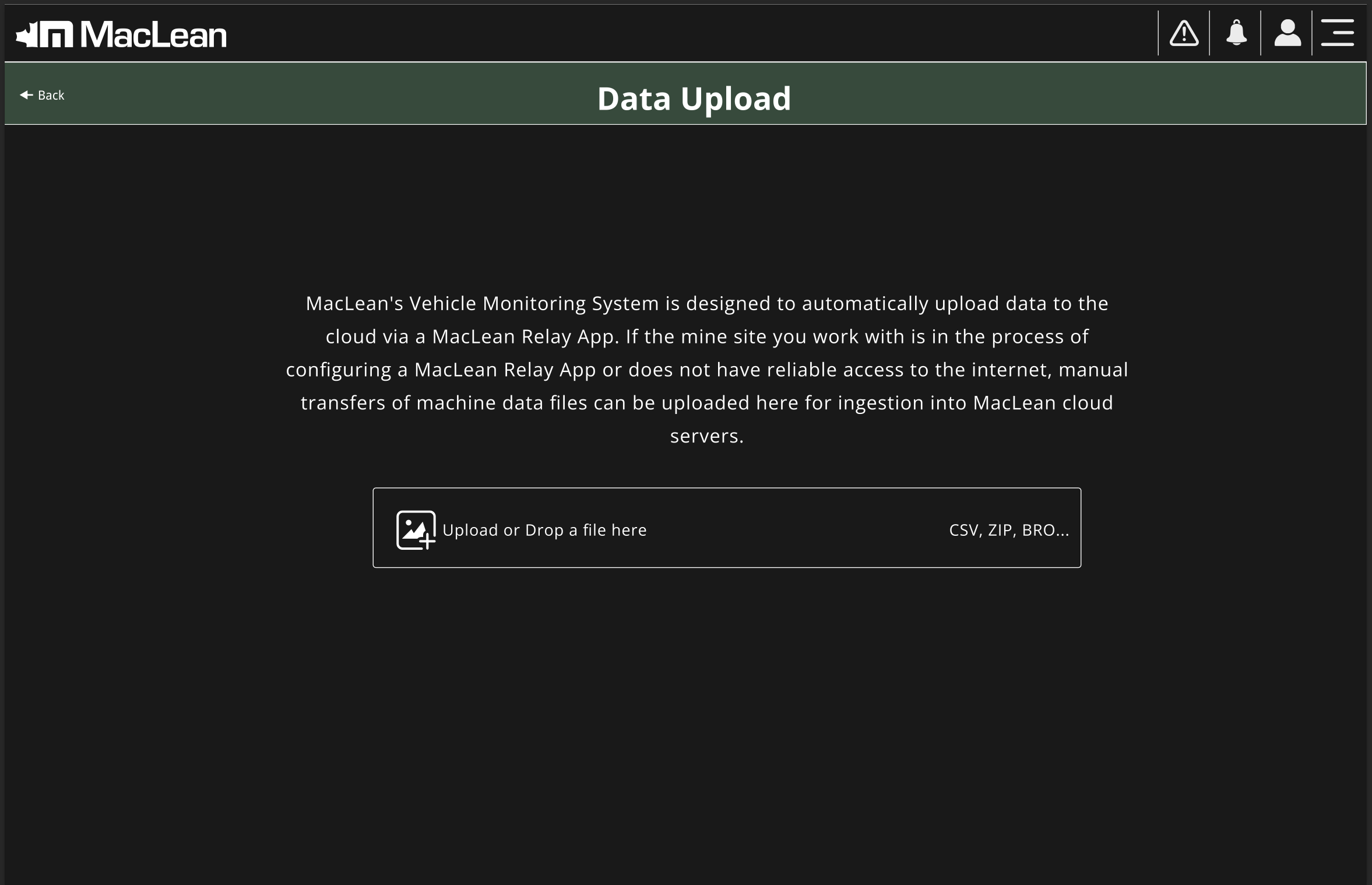

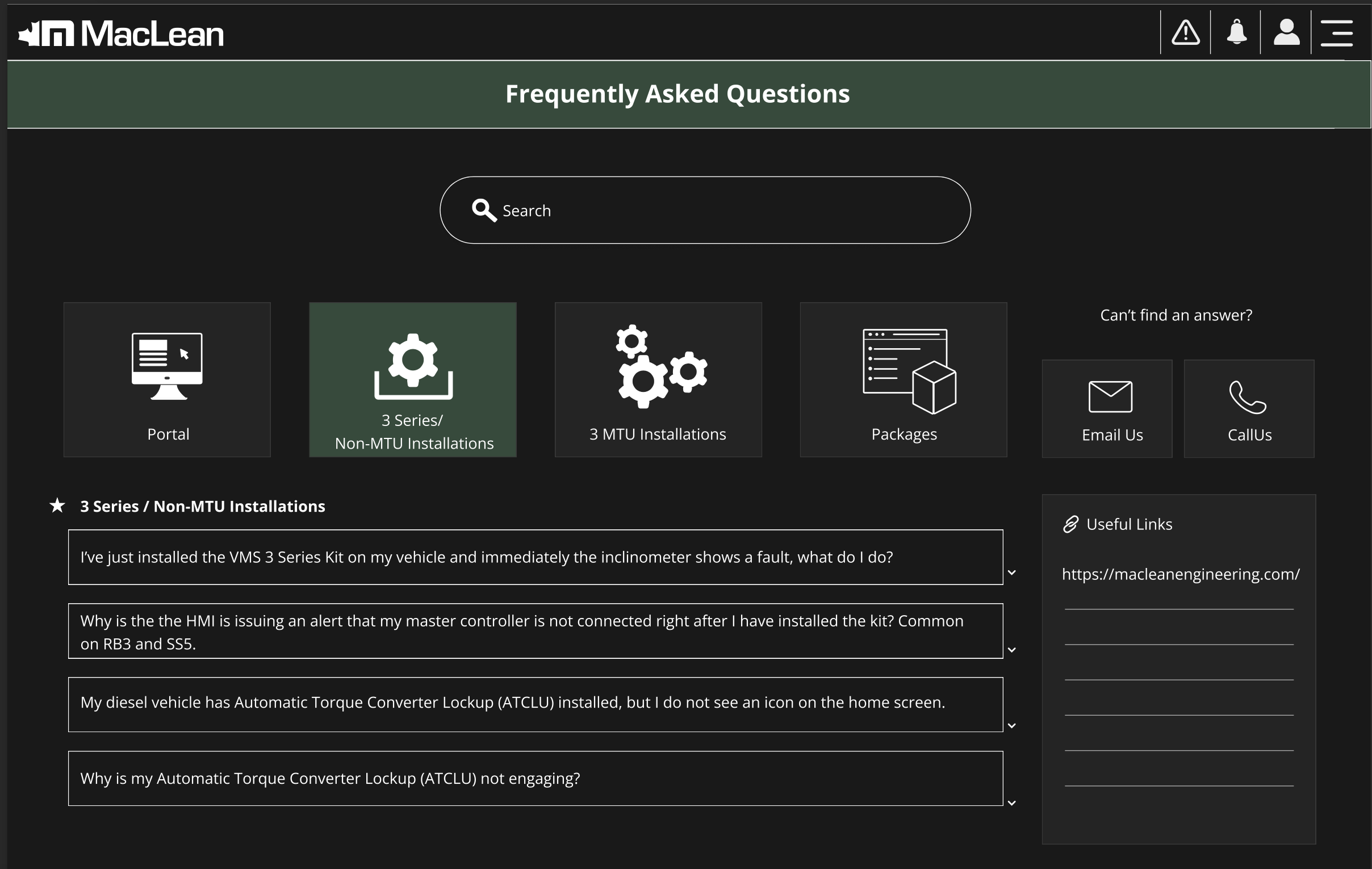

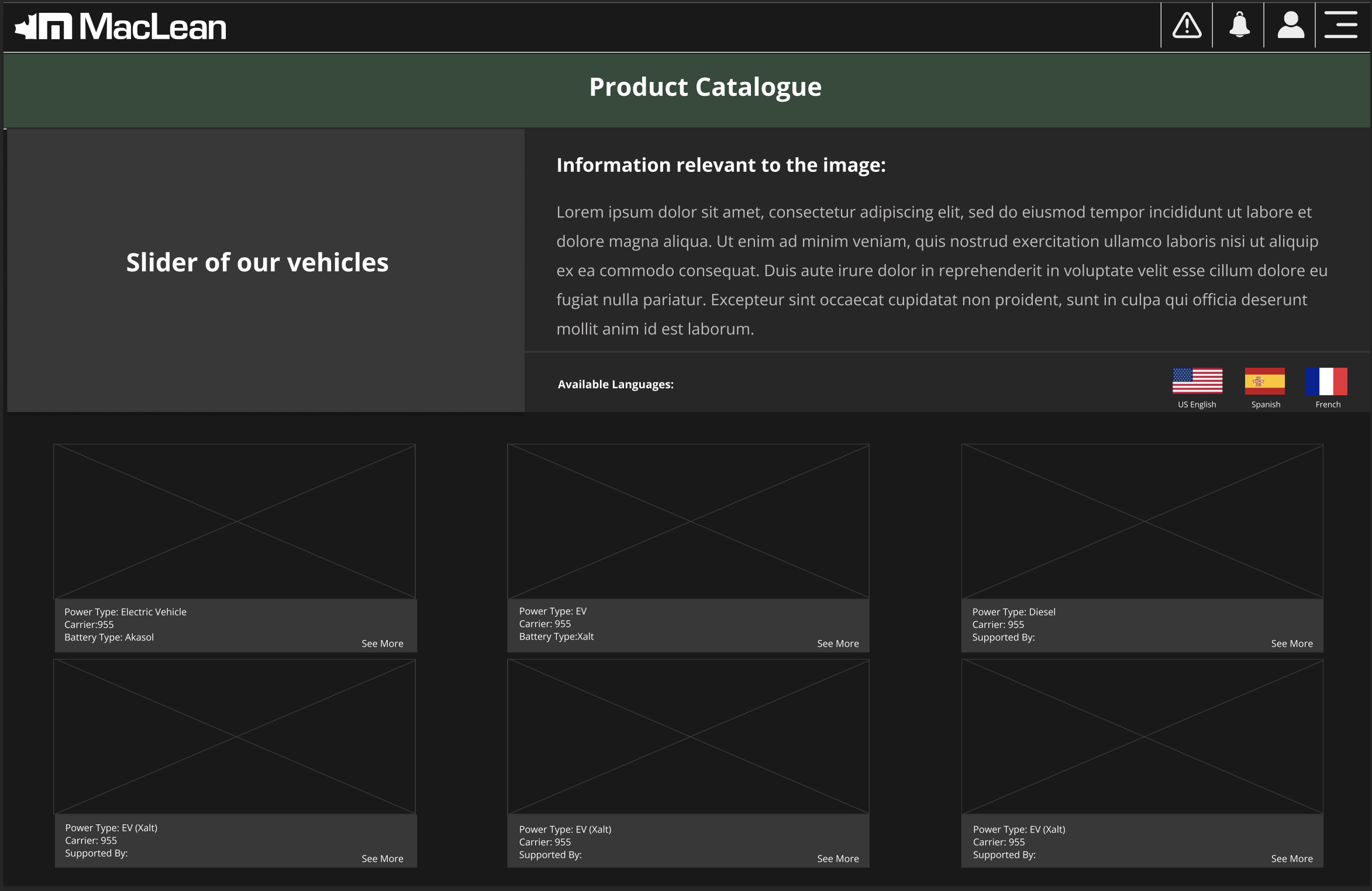

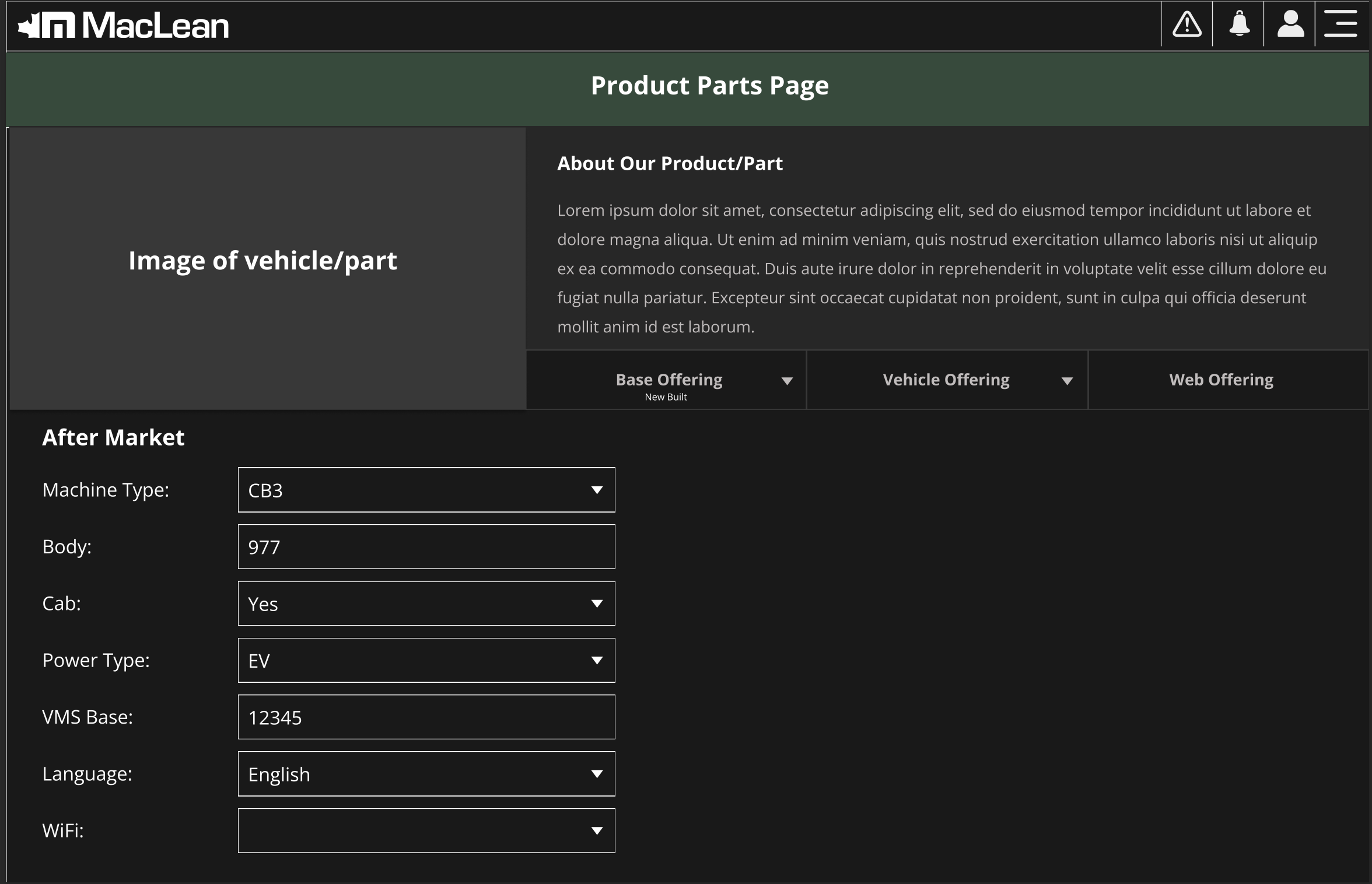

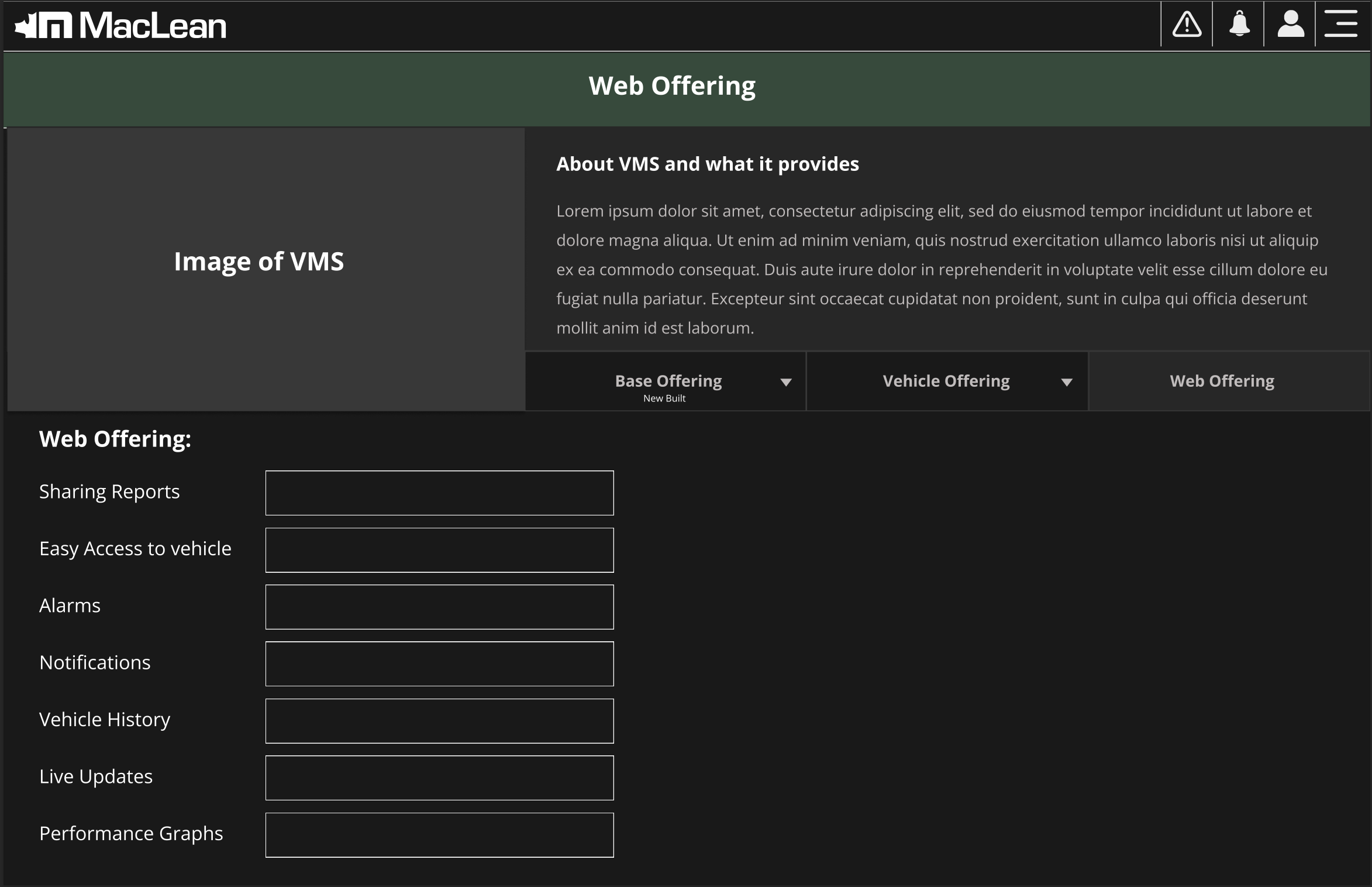

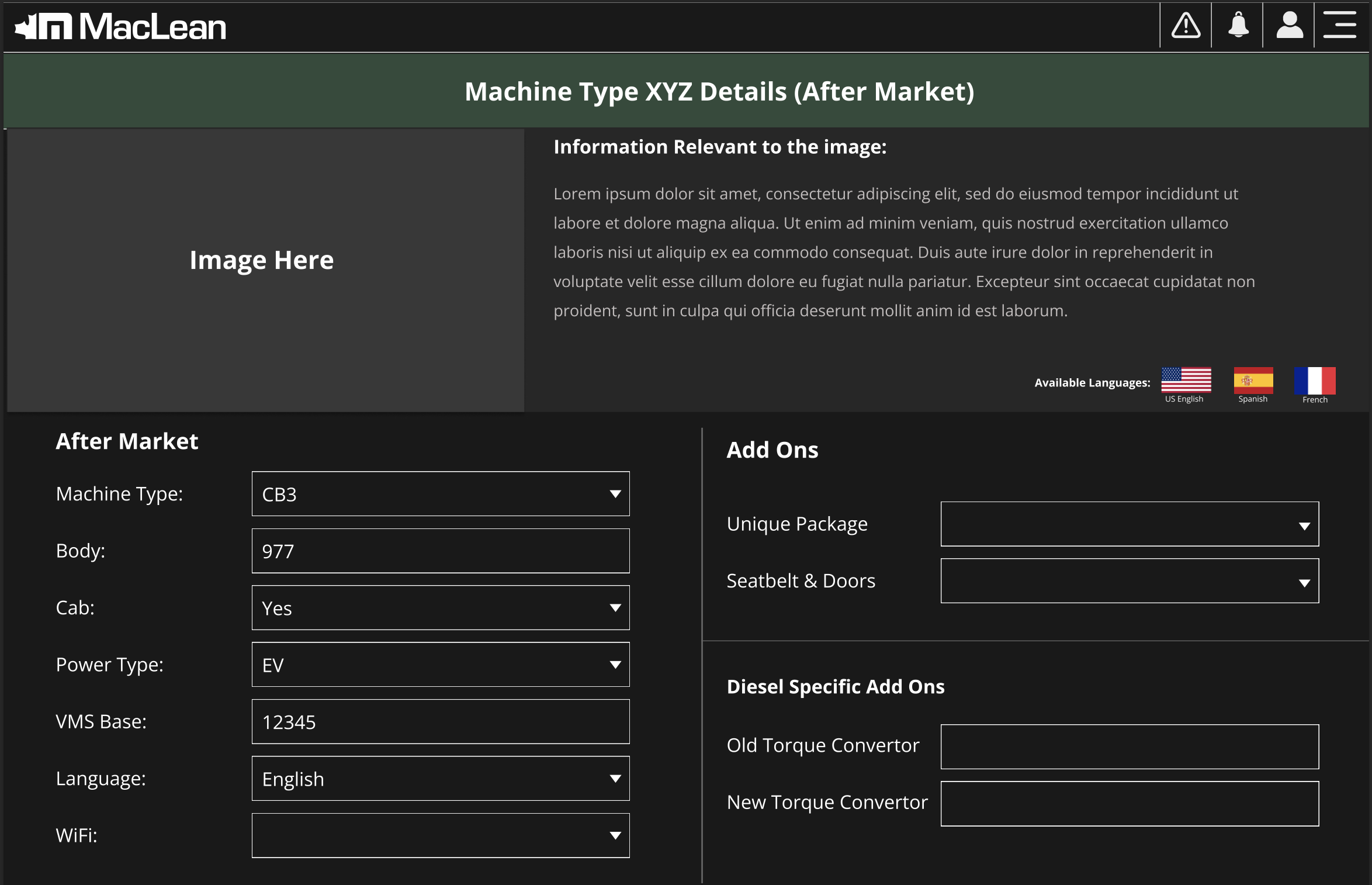

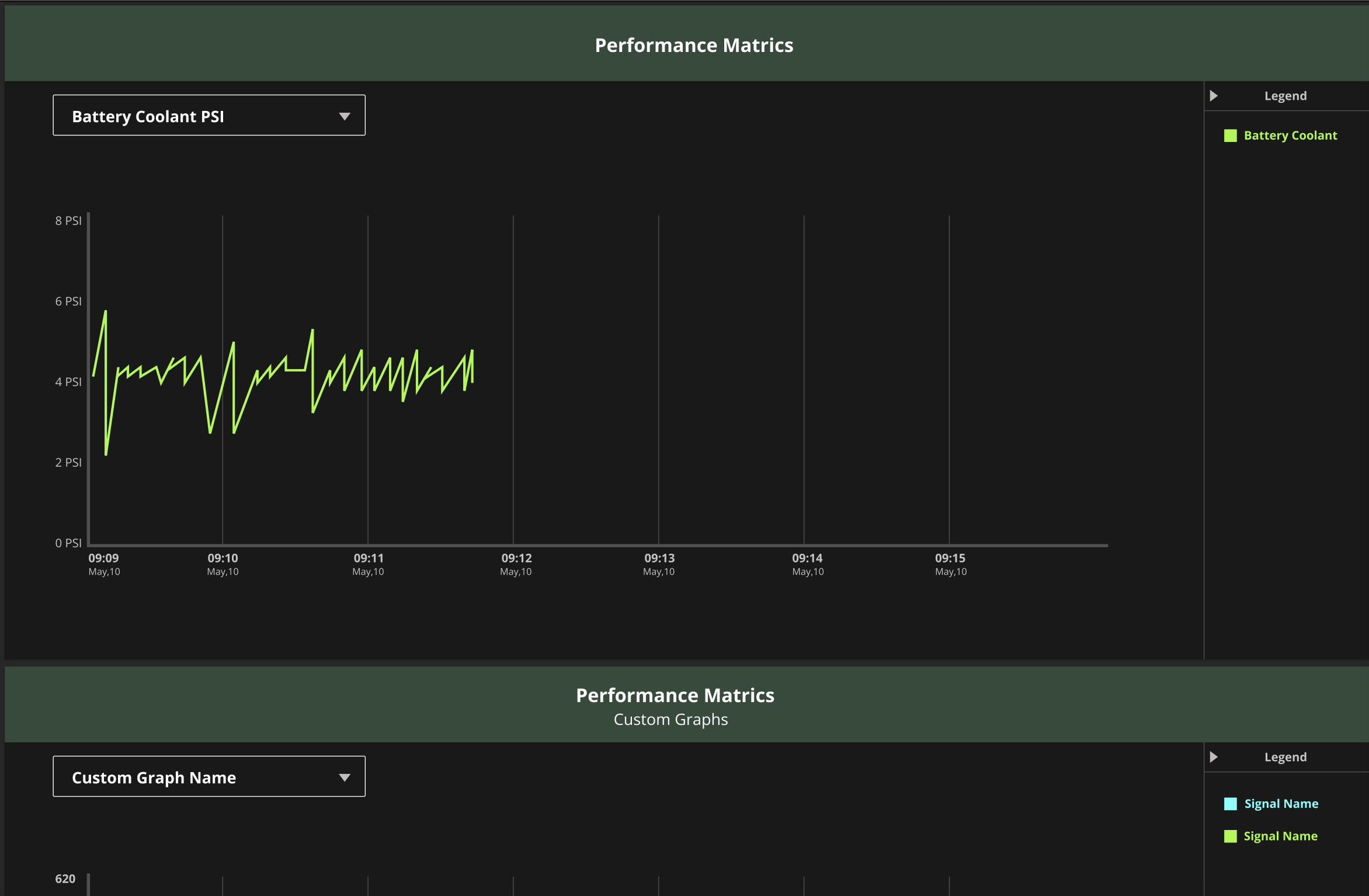

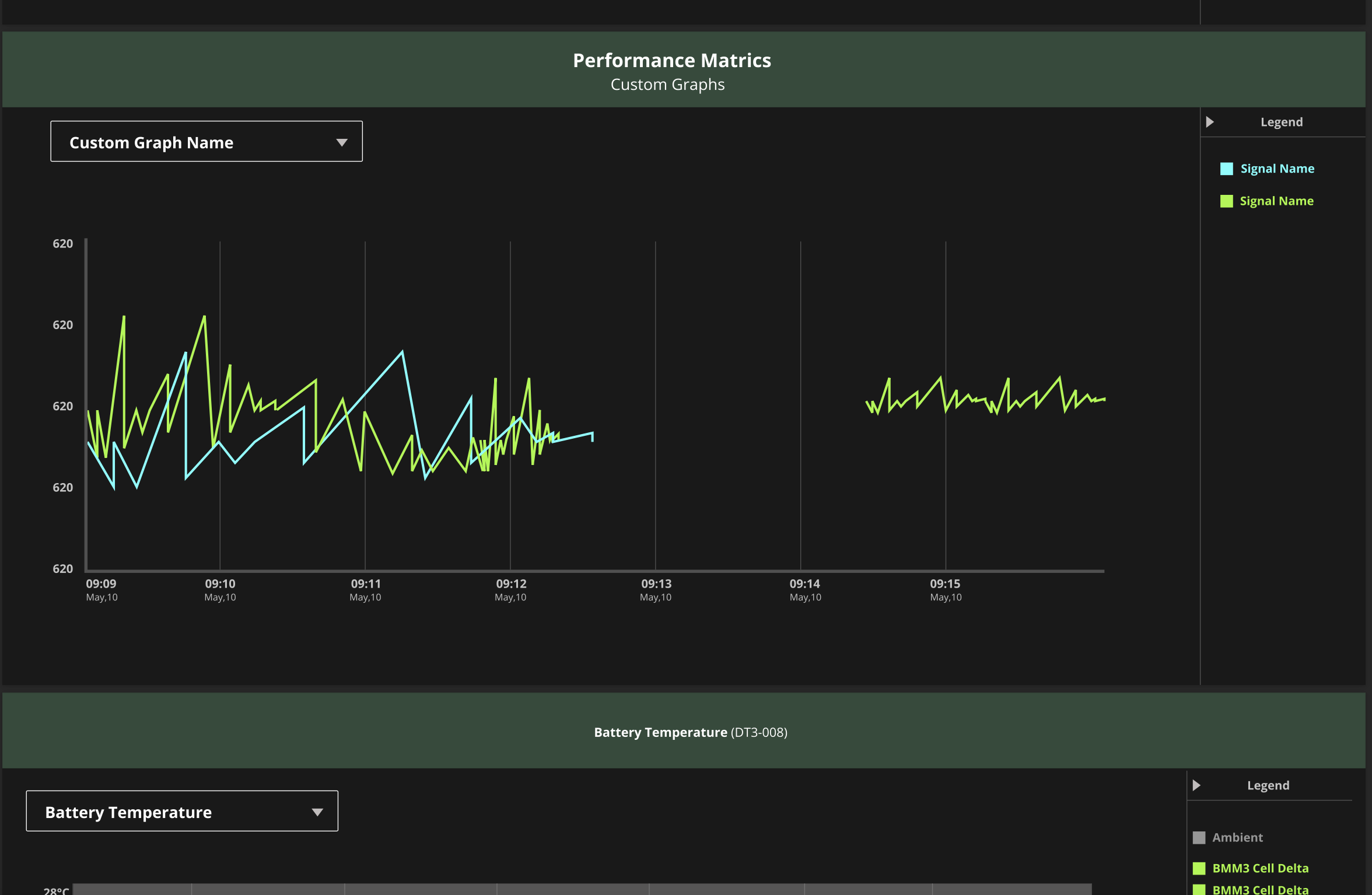

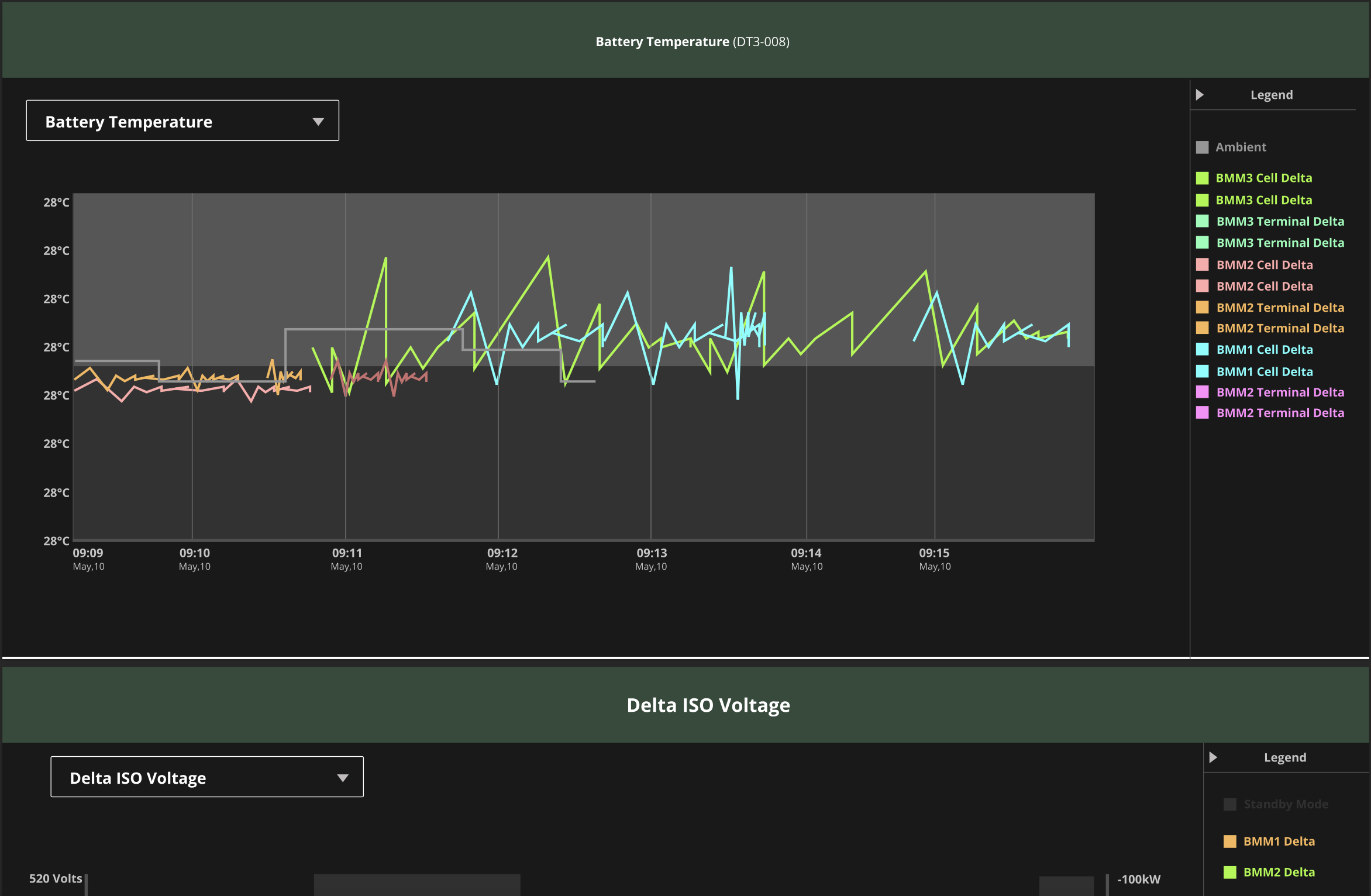

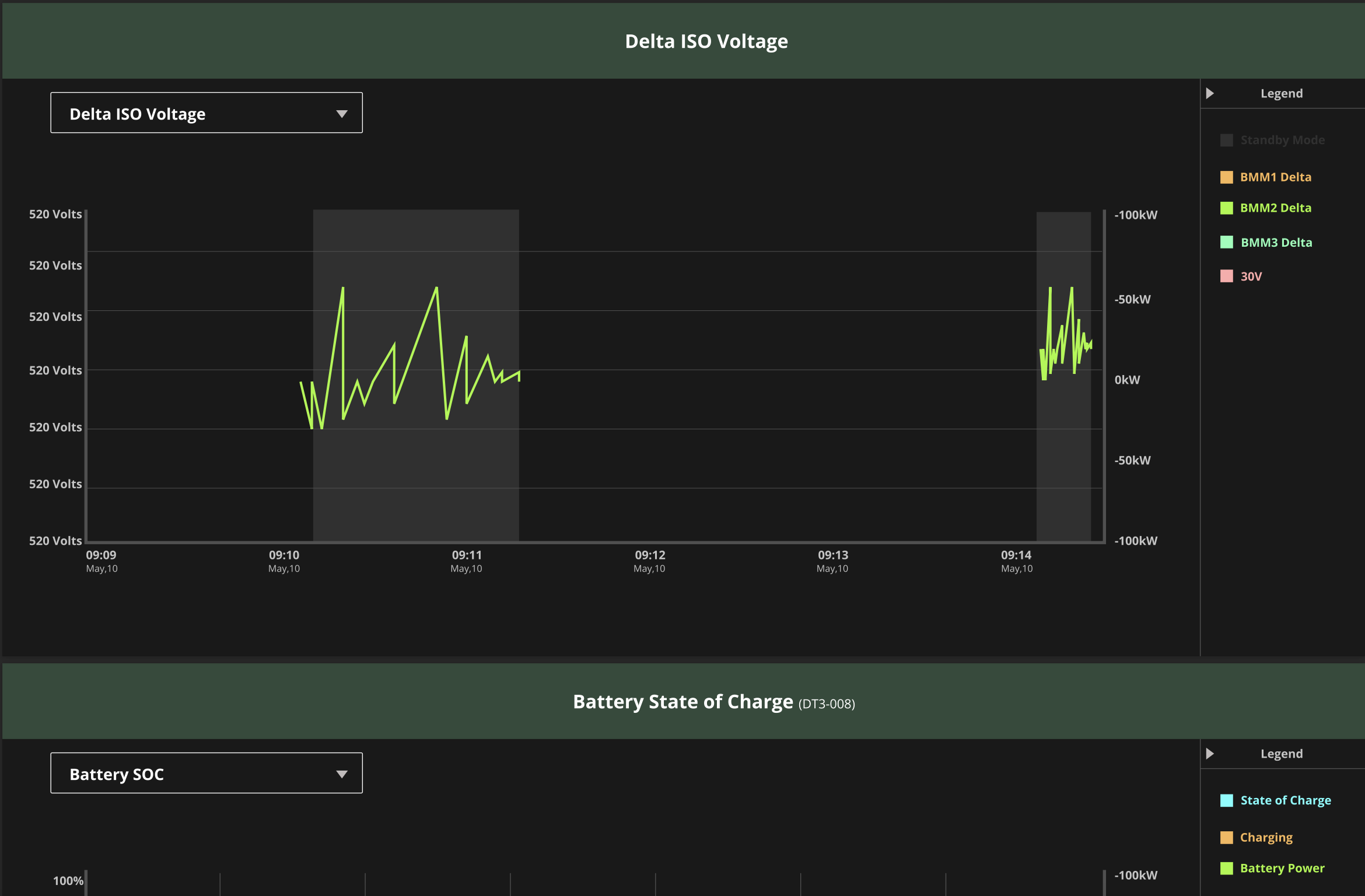

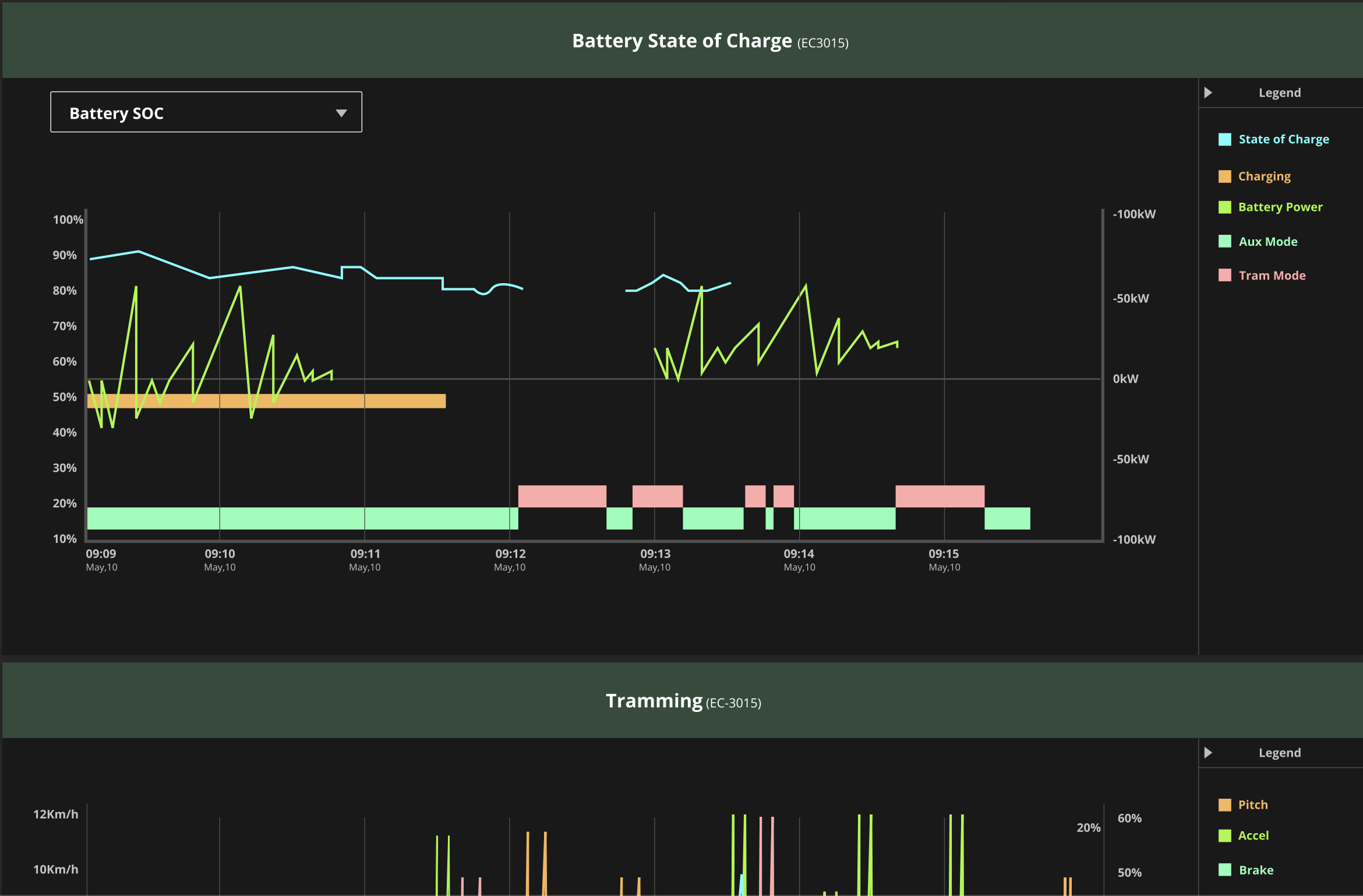

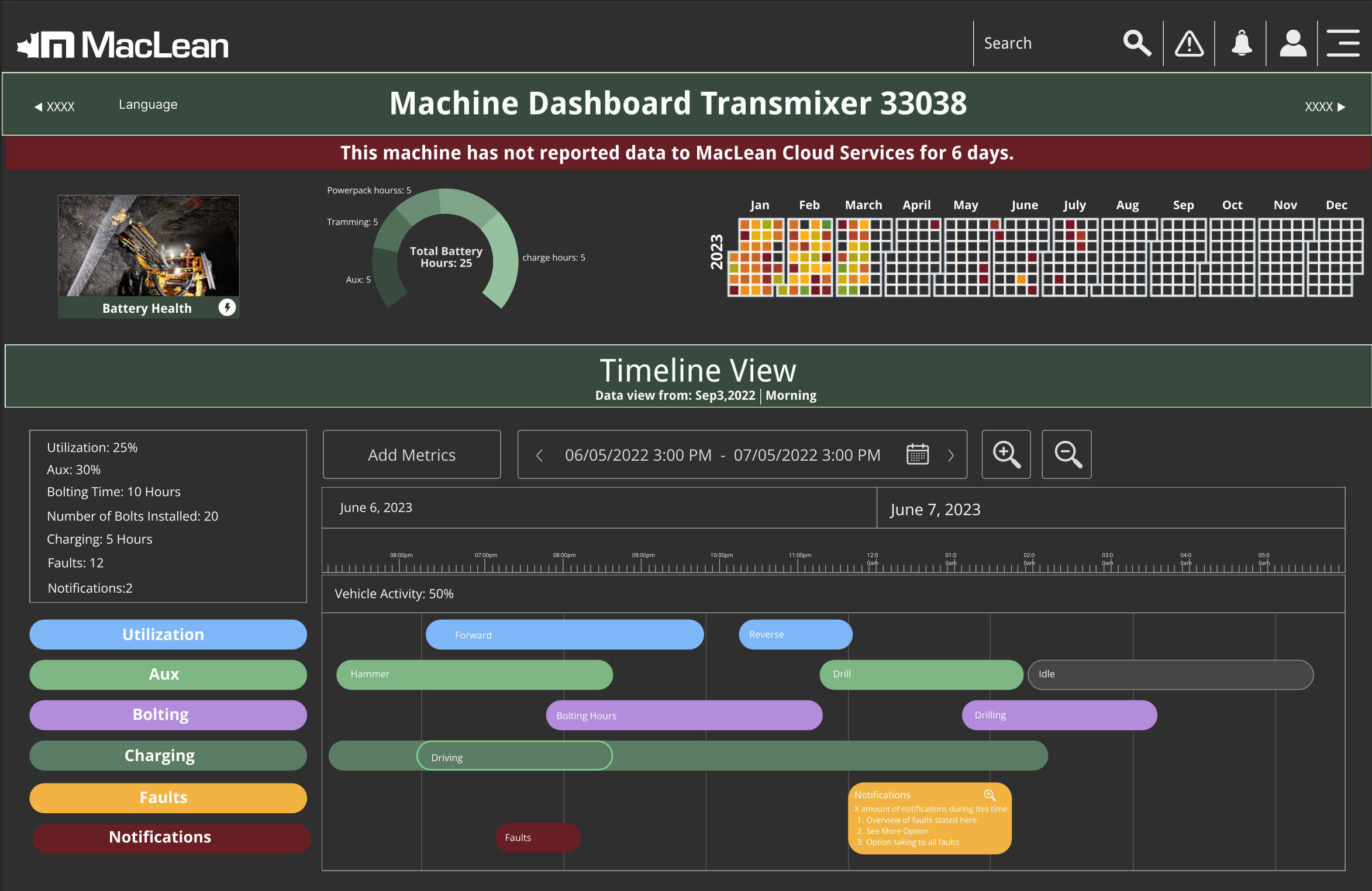

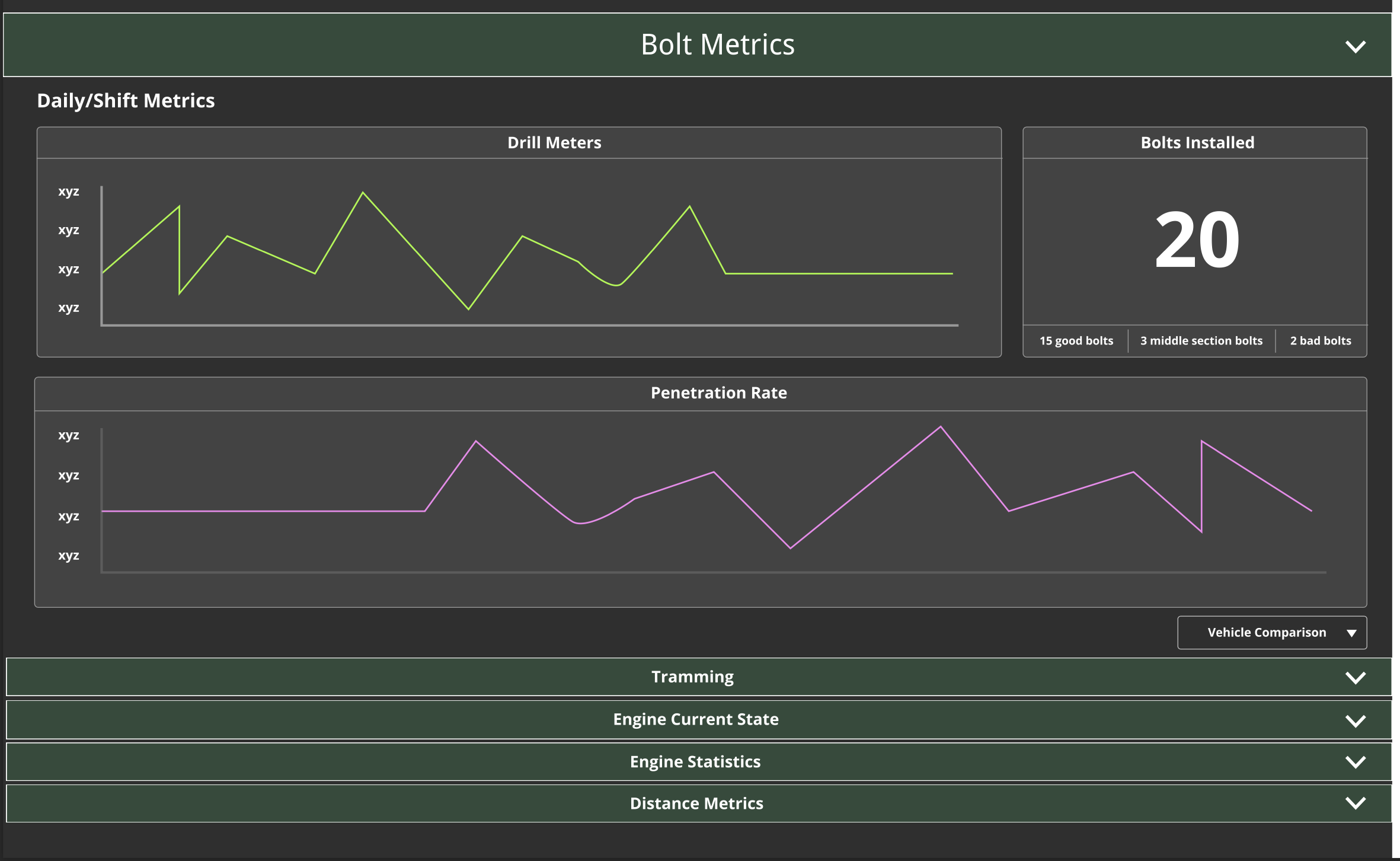

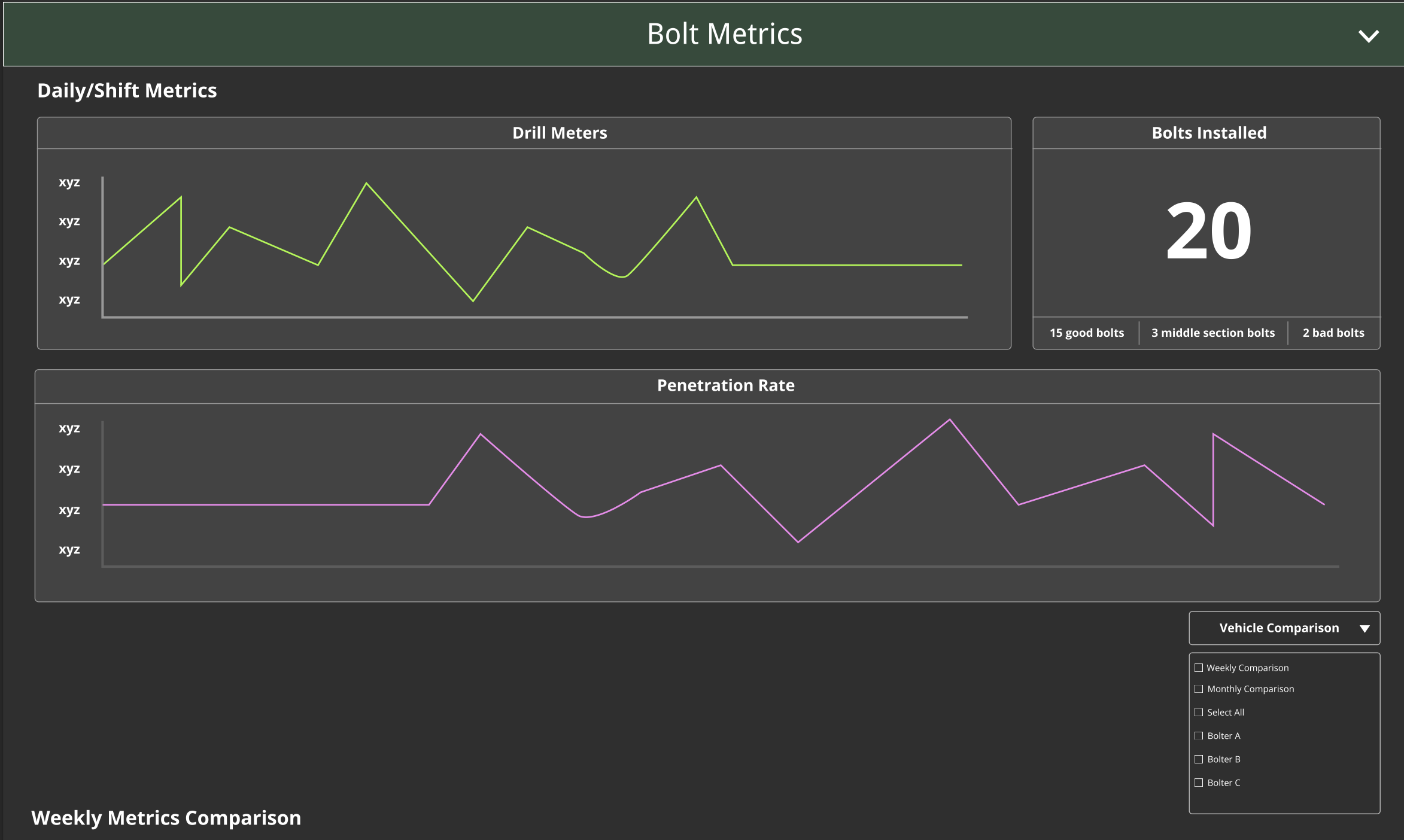

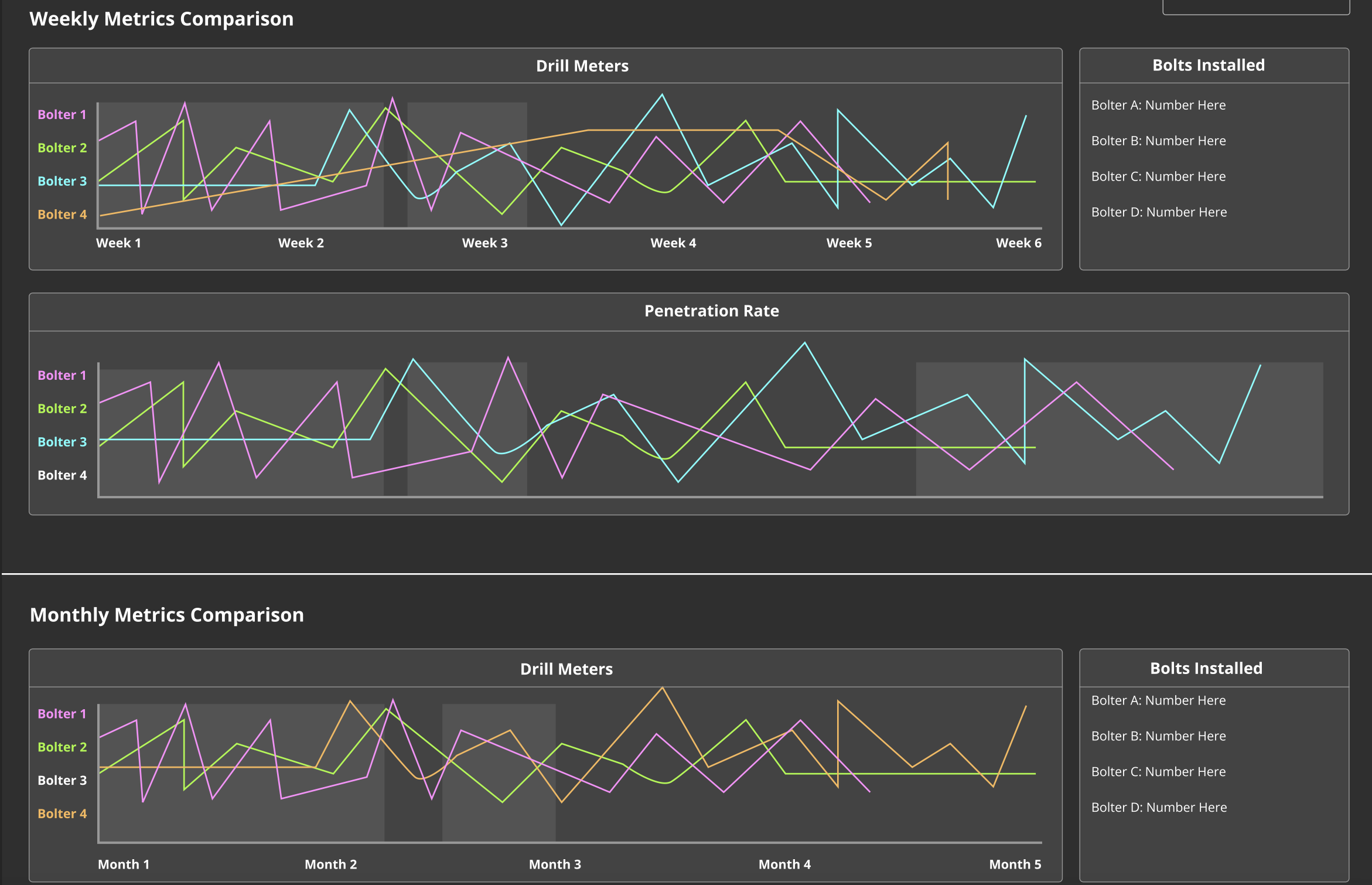

The Vehicle Monitoring System (VMS) is a web-based platform designed to provide real-time and historical visibility into MacLean’s mining vehicles operating underground and above ground.

The product enables customers and internal teams to monitor vehicle health, faults, battery, and engine conditions during long underground shifts where vehicles are disconnected from external networks.

VMS replaced manual, email-based reporting with a centralized digital experience, improving safety visibility, operational efficiency, and customer support in a high-risk mining environment.

Problem & Context

Before VMS, customers depended on daily email reports from internal technicians to understand vehicle performance and issues. This process was slow, fragmented, and difficult to track over time.

For MacLean, this created operational overhead and posed a competitive risk, as key competitors were already offering digital monitoring solutions. In a safety-critical mining environment, delayed or missed information could lead to serious consequences.

The environment that MacLean Vehicles works in.

My Role & Ownership

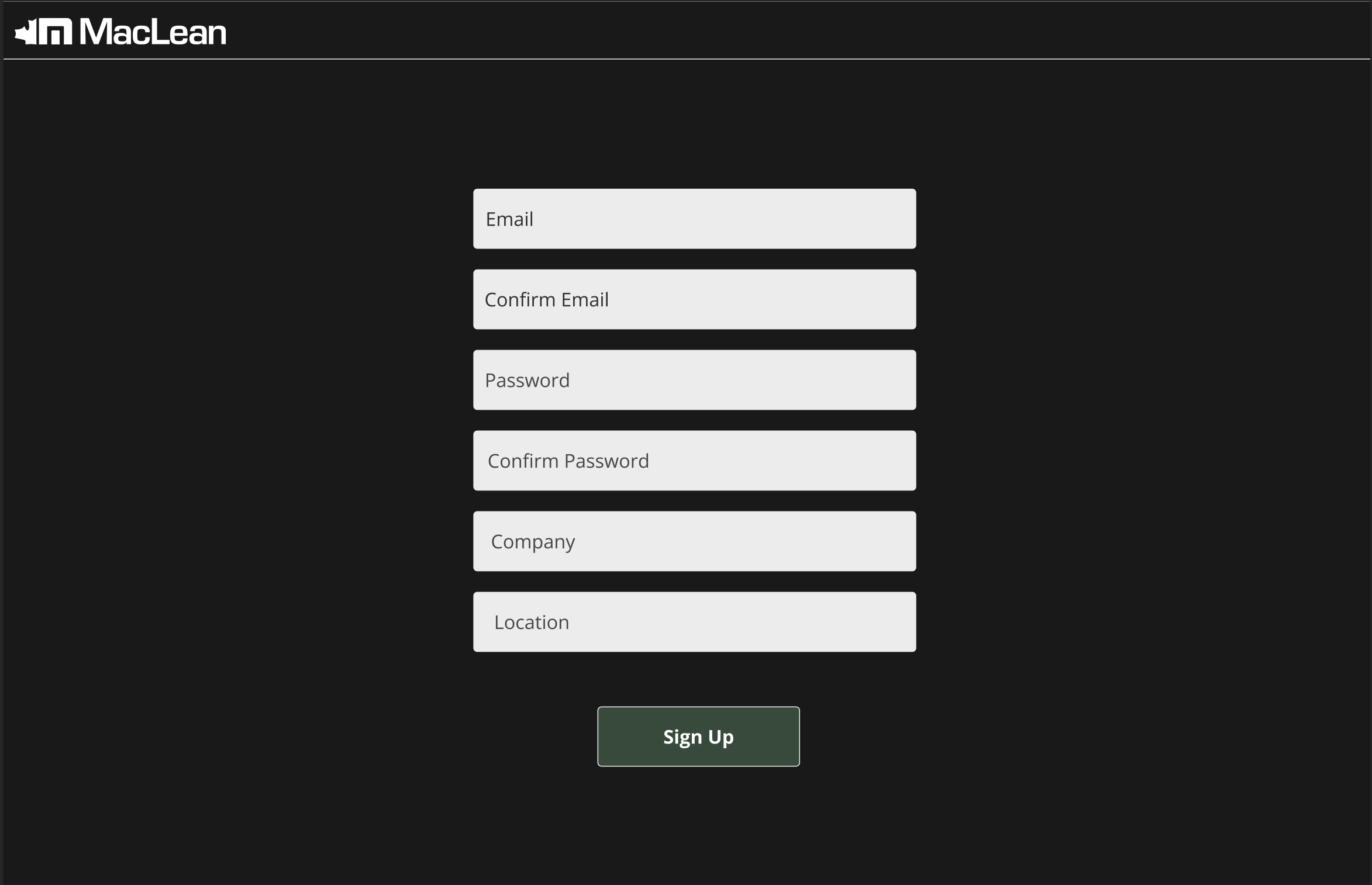

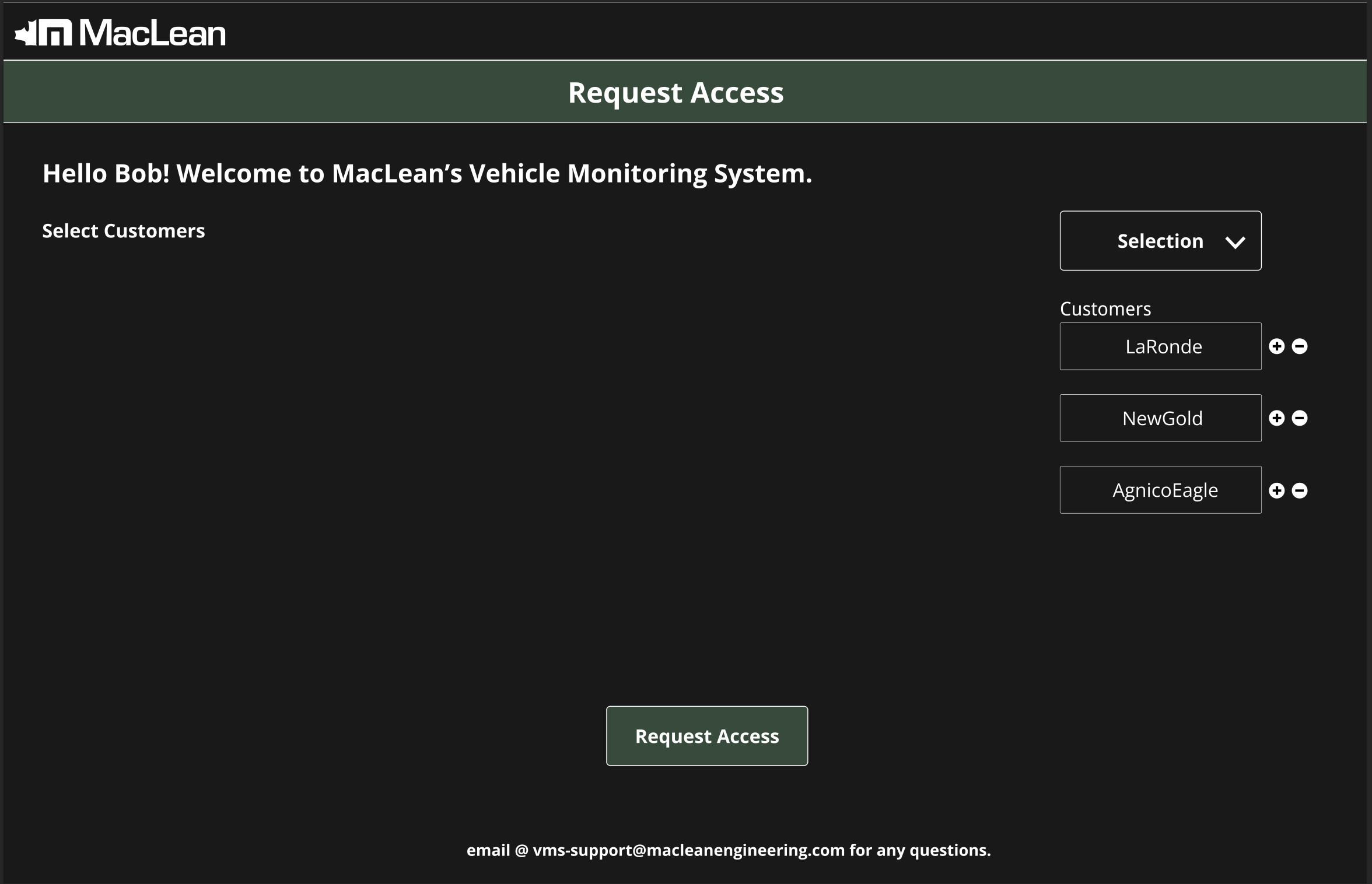

I was the sole Product / UX Designer responsible for the end-to-end design of the Vehicle Monitoring System.

I owned:

• Discovery and user research from scratch

• User interviews, surveys, and field observations with customers and internal teams

• Creation of personas, empathy maps, and experience maps

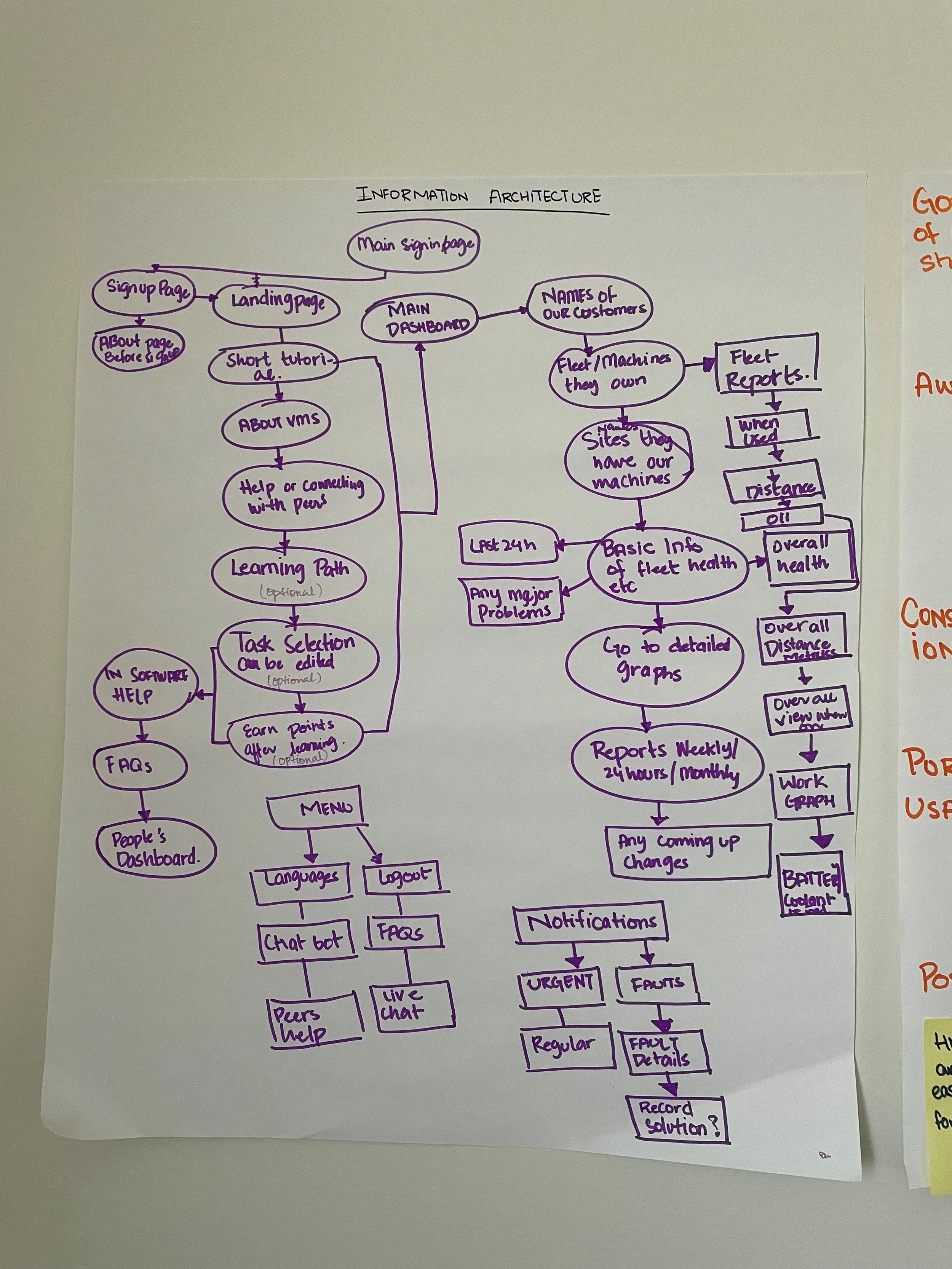

• Definition of user flows, information architecture, and interaction patterns

• Wireframes, high-fidelity prototypes, and production-ready design specifications

• Design system components, iconography, and visual assets aligned with company branding

• Planning and running usability testing sessions

• Iterating designs based on user feedback and technical constraints

• Close collaboration with product managers, engineers, technicians, and operators

Research & Discovery

Methods

• User interviews

• Surveys

• Task-based usability testing

• Observation

• Card sorting

Participants

30–40 users across customers, technicians, and internal teams.

Key Insights

Insight 1

What we learned

Operators lacked a centralized, reliable way to access detailed vehicle information, making it difficult to quickly understand vehicle status, history, and emerging issues.

Why it mattered

This fragmentation increased the risk of delayed issue resolution and inconsistent decision-making — a critical concern in a safety-sensitive mining environment.

⸻

Insight 2

What we learned

Users lacked continuous visibility into vehicle status, except during physical inspections or scheduled updates.

Why it mattered

Limited visibility increased the risk of missed or delayed responses to vehicle faults, increasing safety and operational risk.

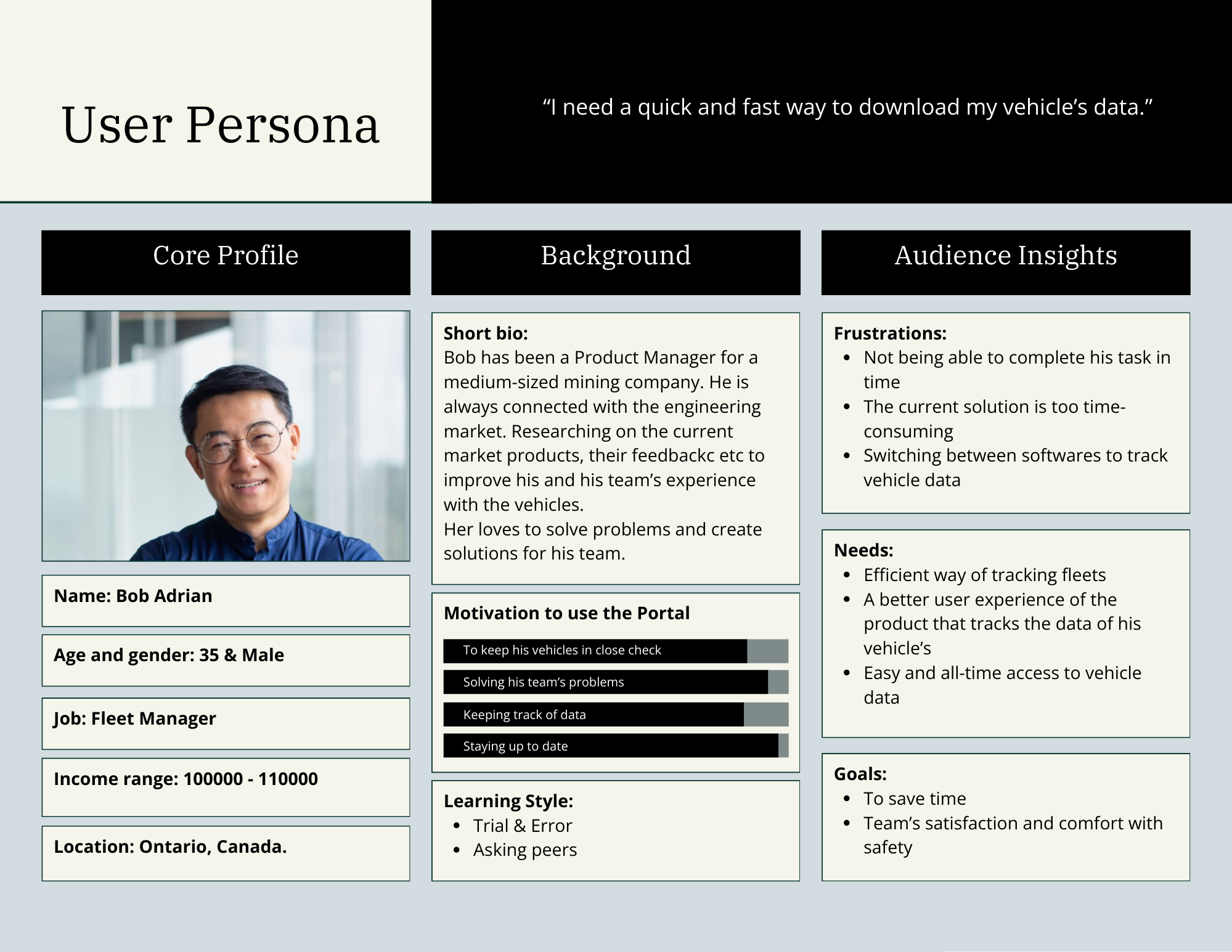

User Persona

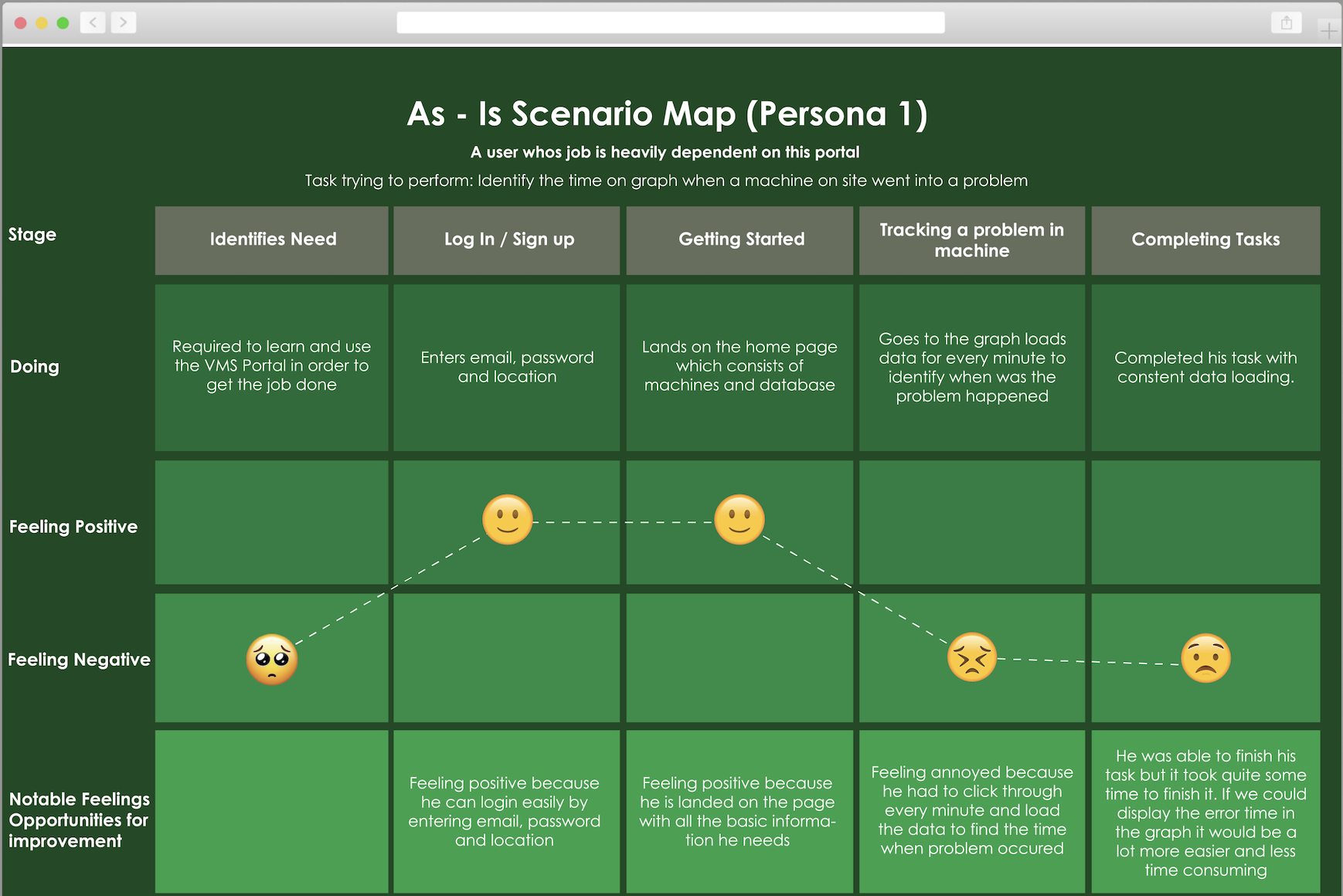

As-Is Scenario Map

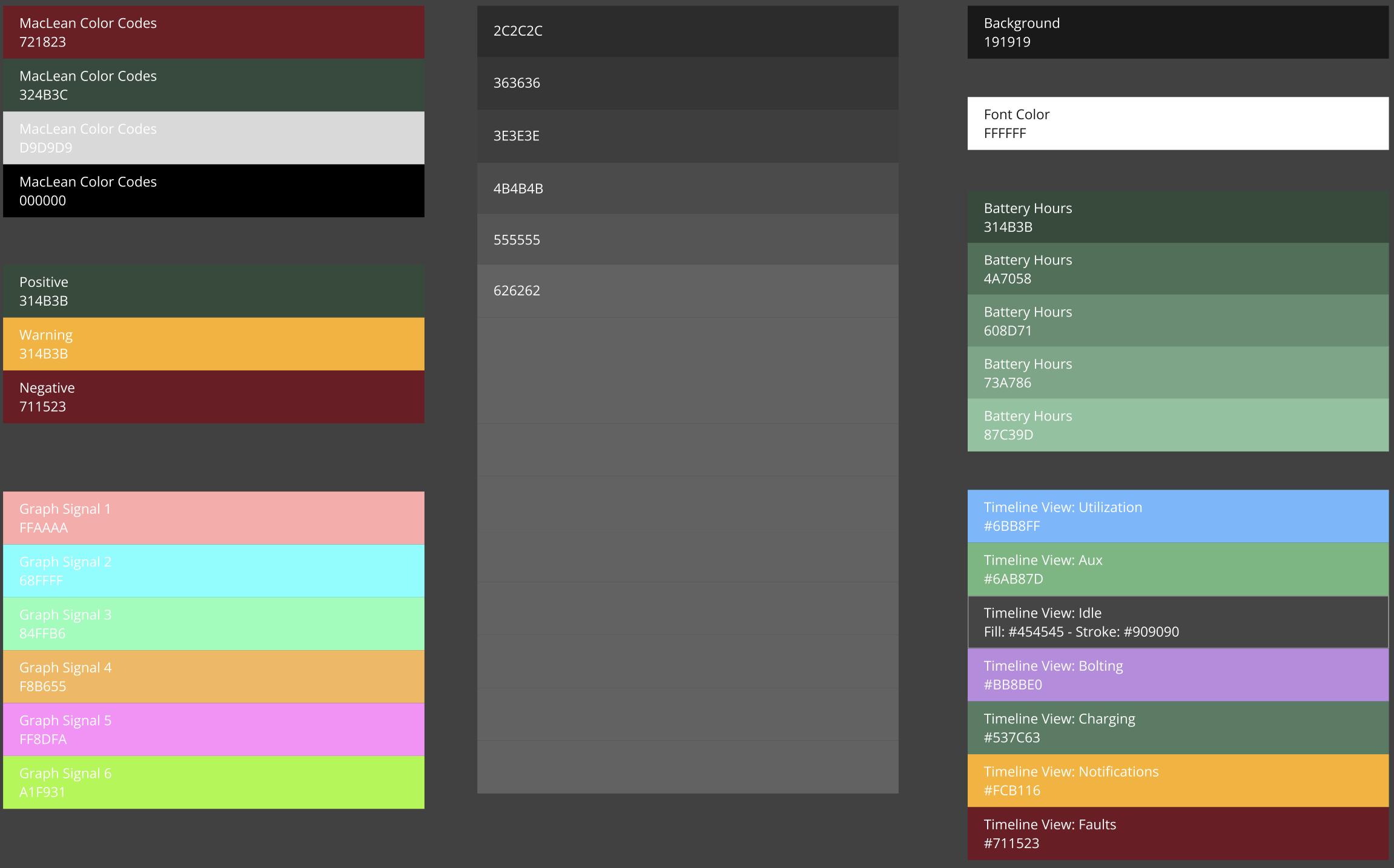

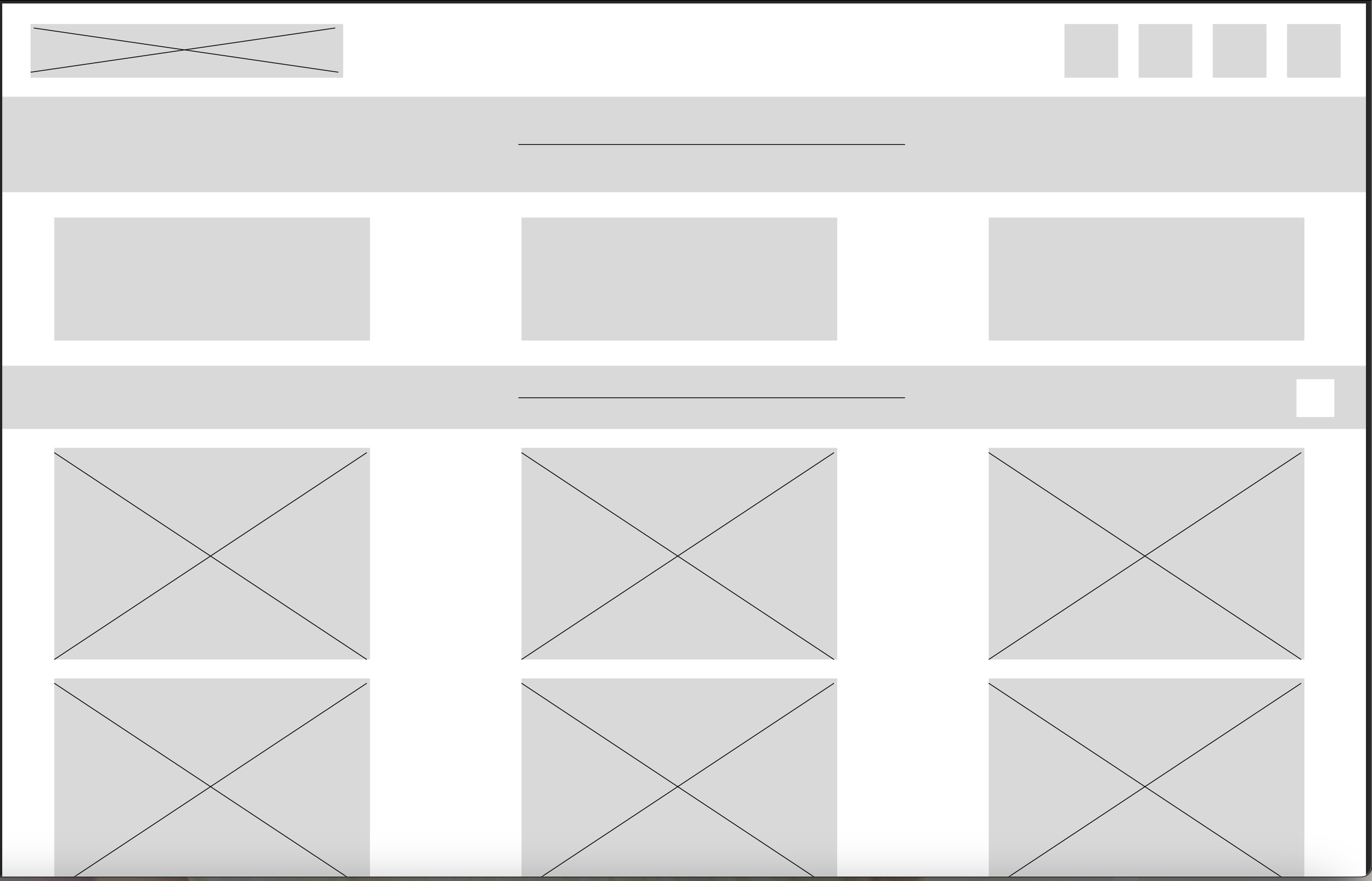

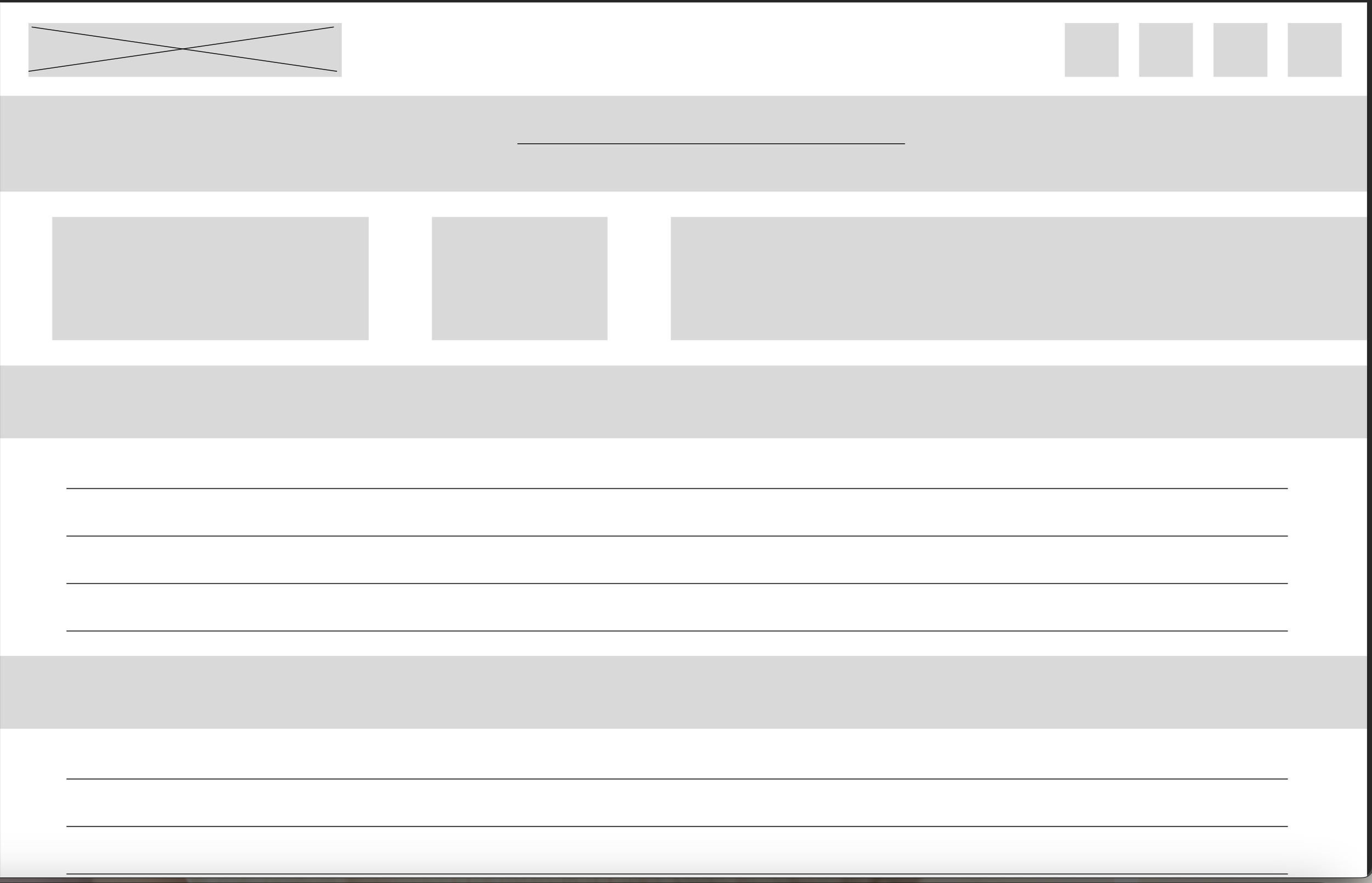

Initial Architecture, Colour Palette & Fonts

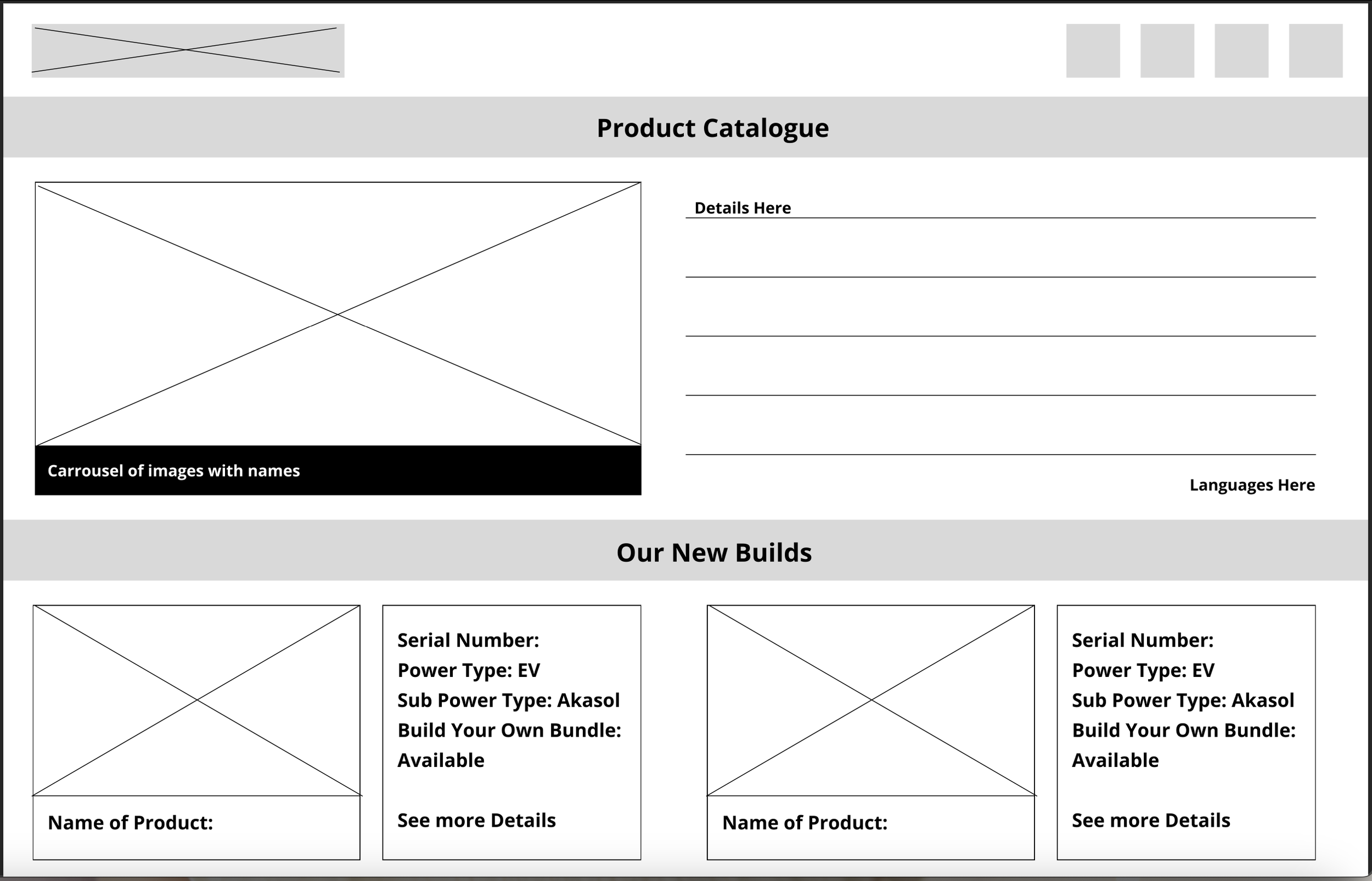

Some screens from the initial wireframes

From Insights to Design Focus

These insights informed the information architecture and interaction model, ensuring users could quickly access critical vehicle data without unnecessary cognitive load.

Design Decisions

Design Decision: Centralized Vehicle Overview

• Insight

Users relied on fragmented communication to understand vehicle status.

• Decision

I designed a centralized dashboard that surfaces vehicle health, maintenance status, and fault alerts in one place.

• Why it mattered

This reduced reliance on email updates and allowed faster, safety-critical decision-making.

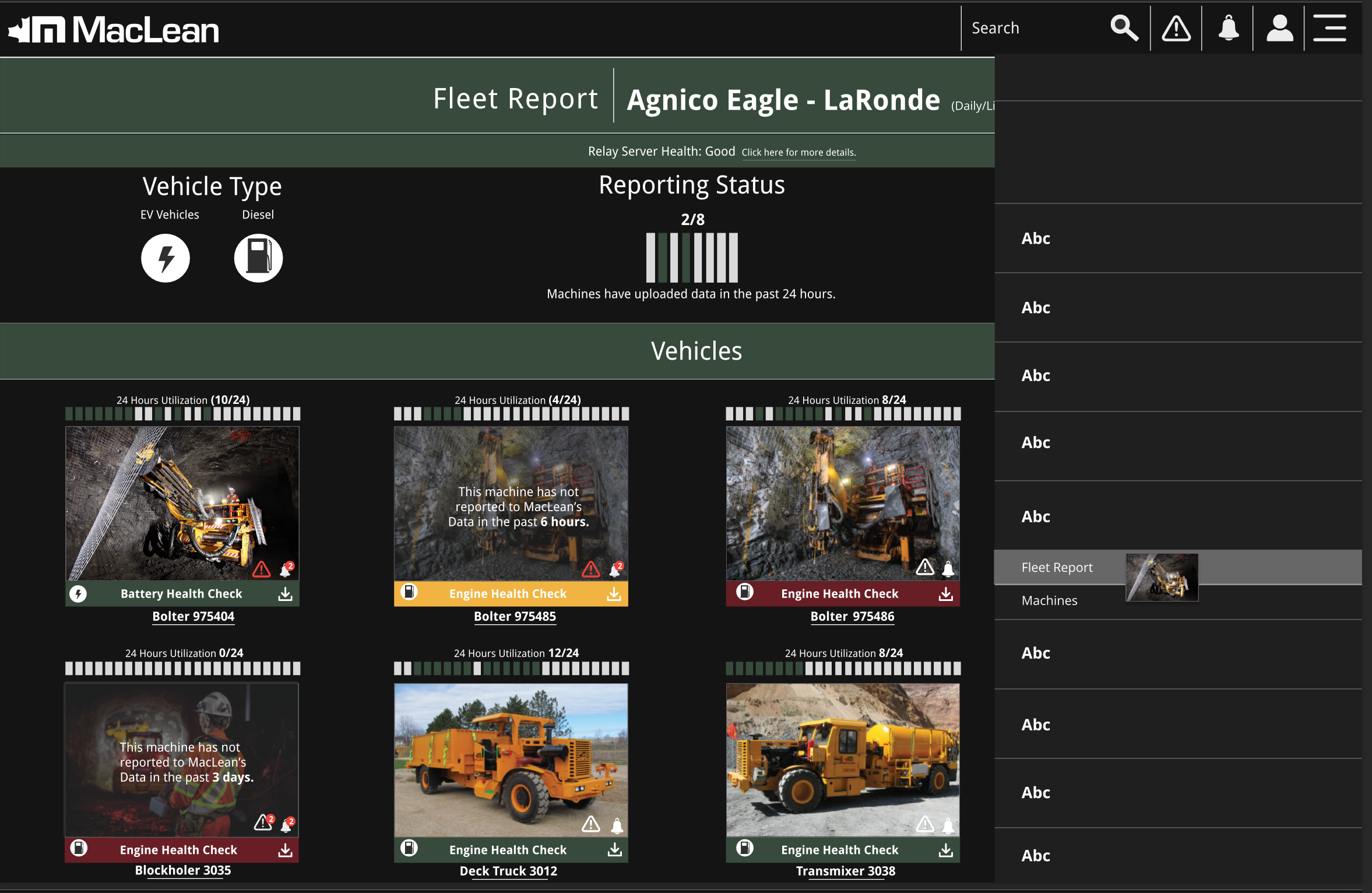

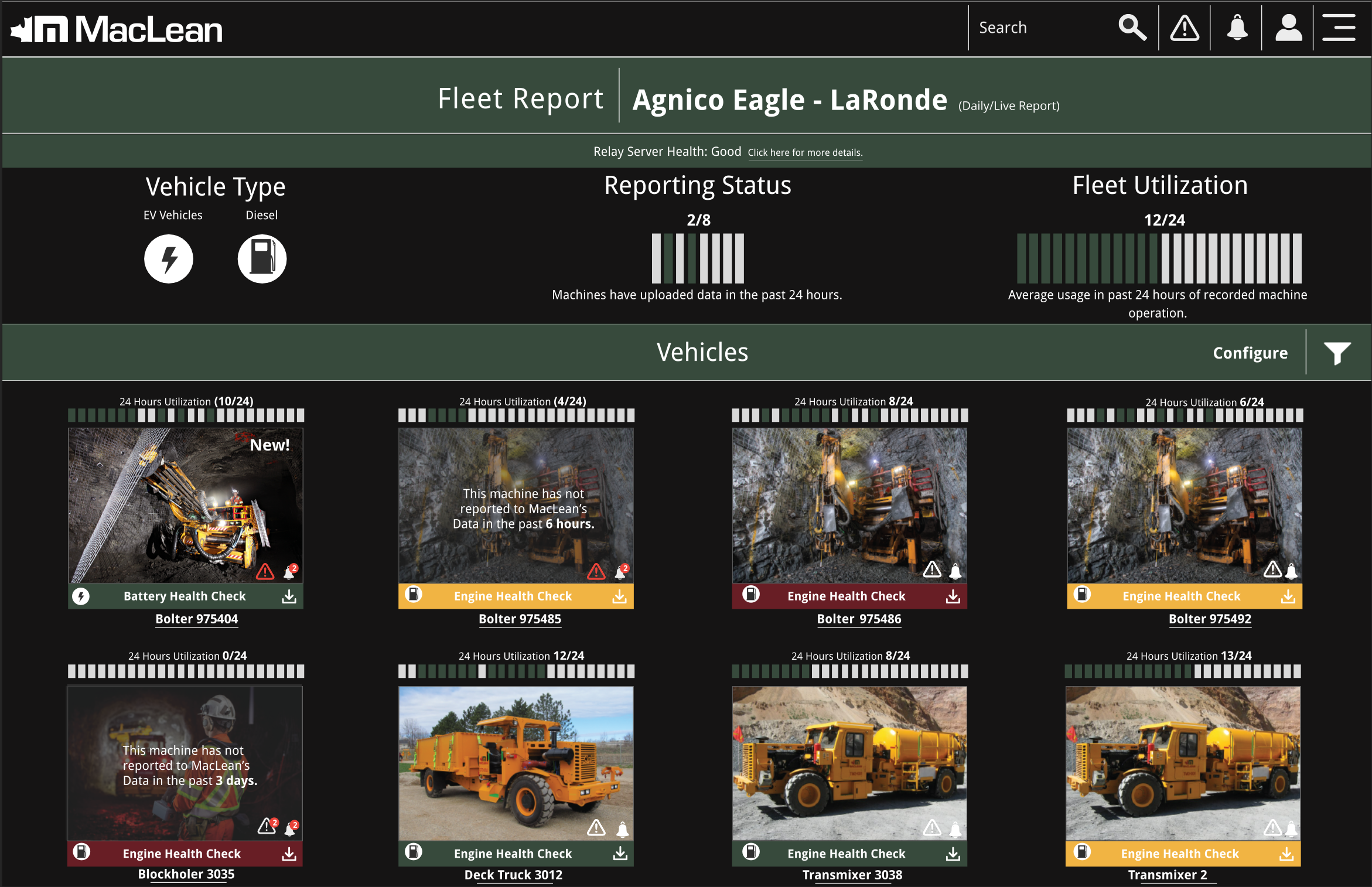

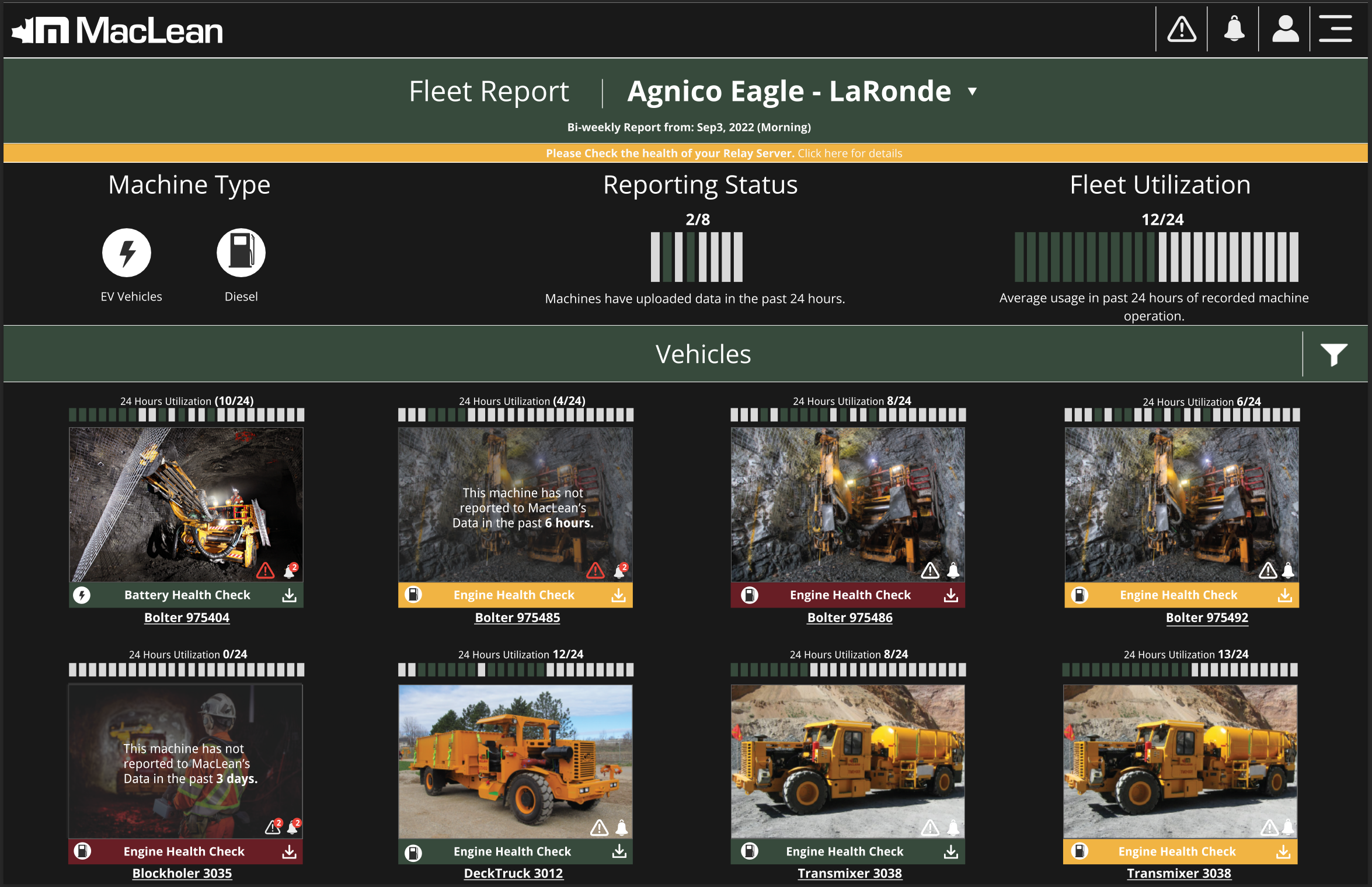

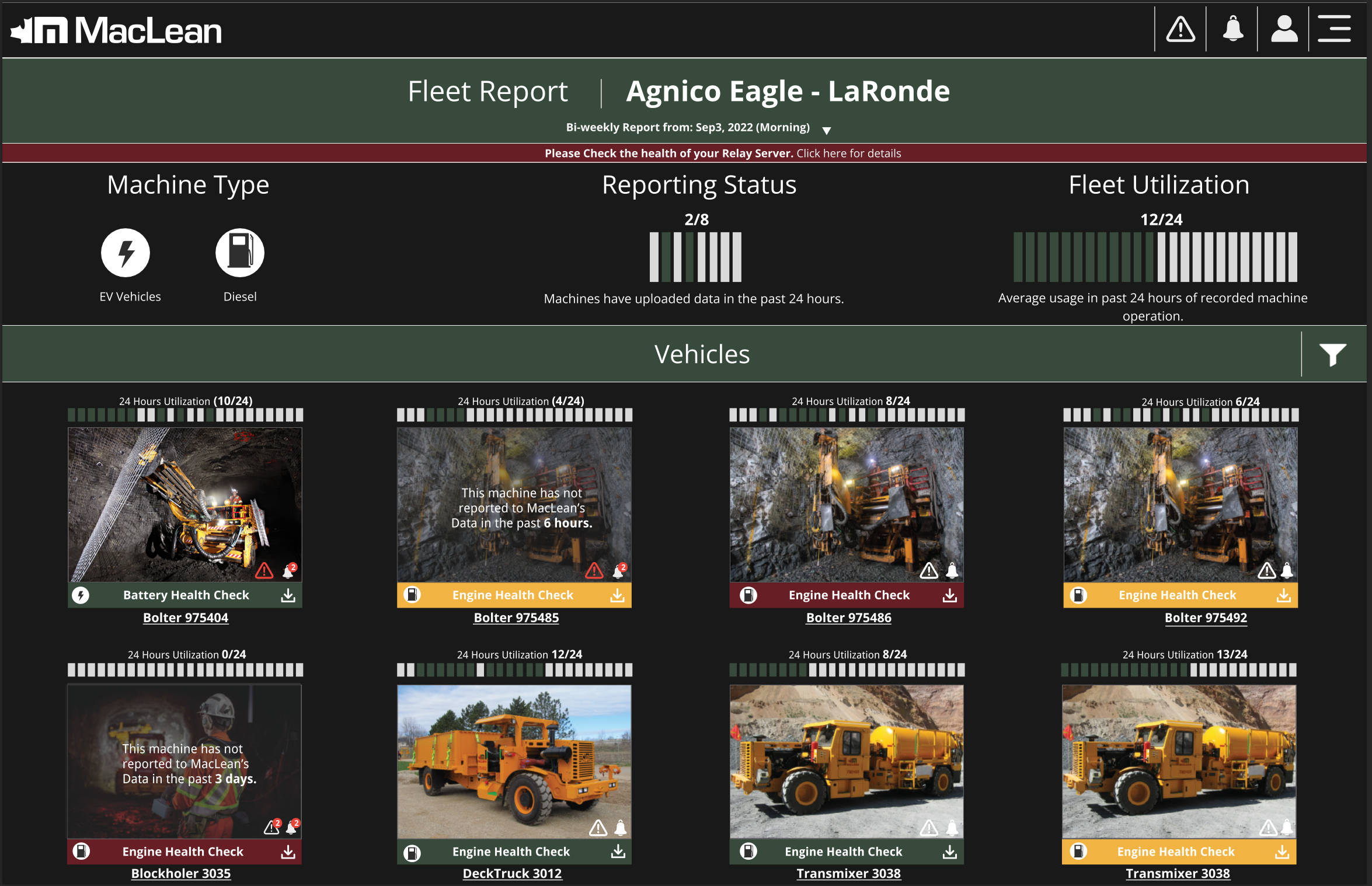

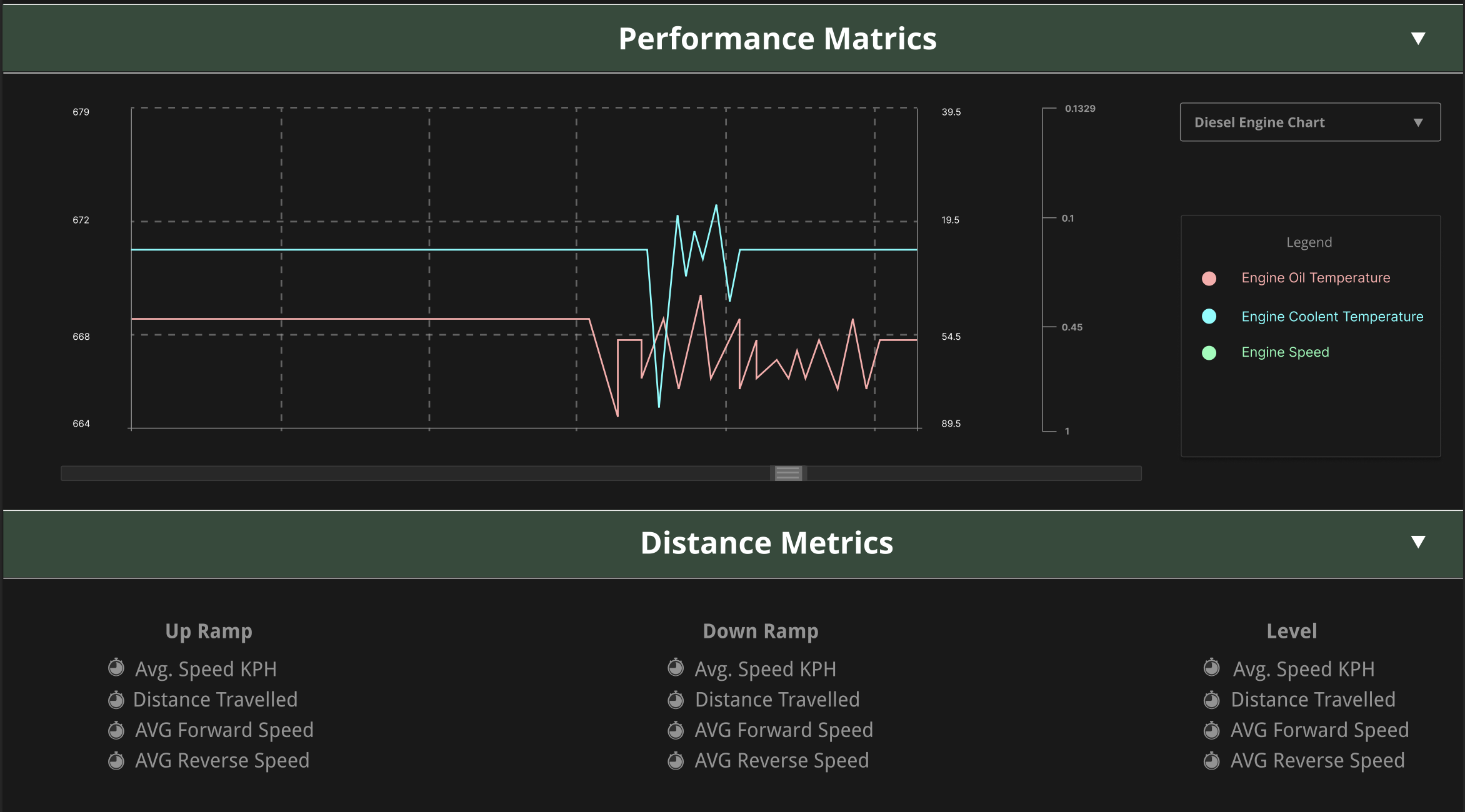

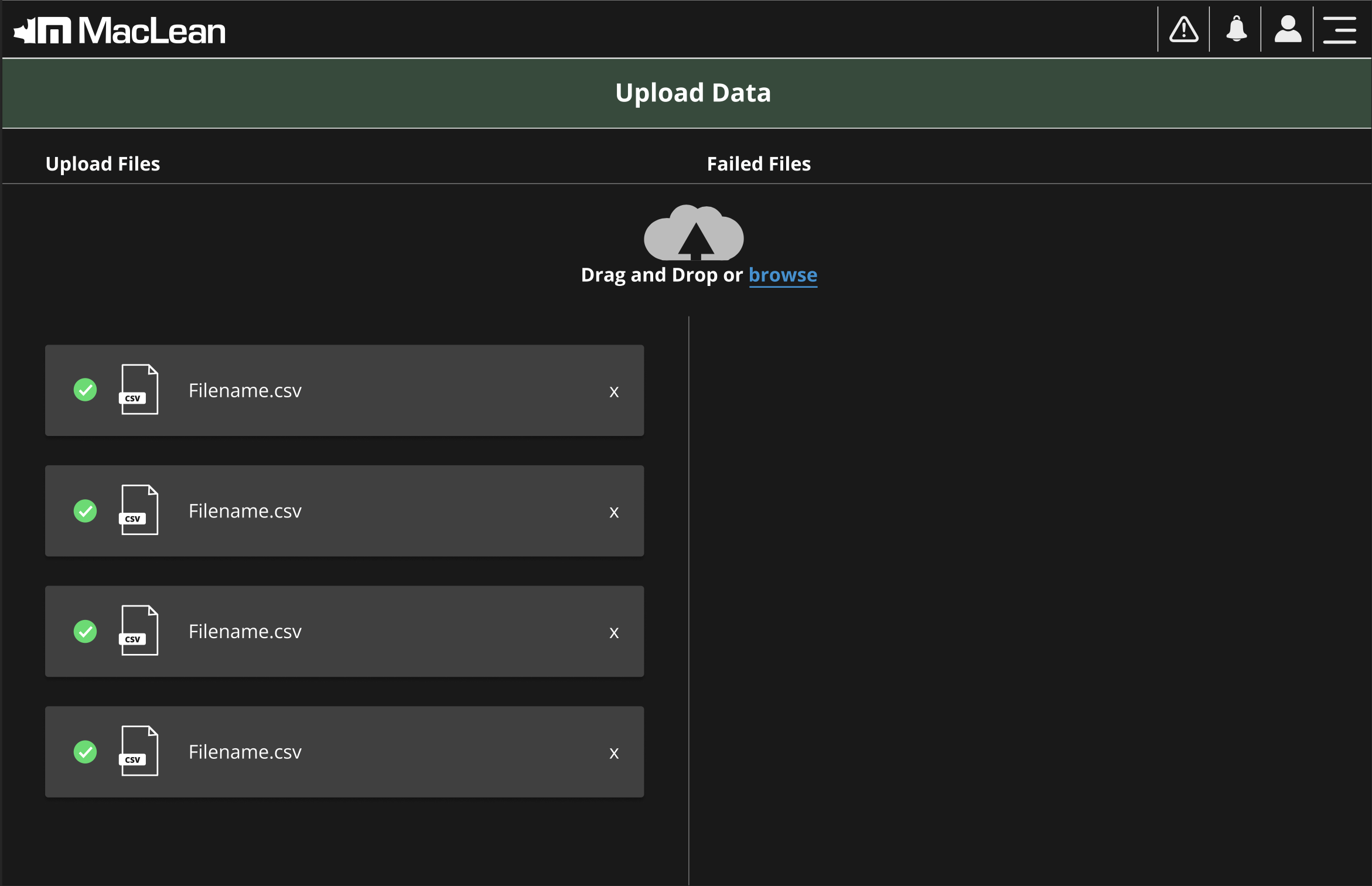

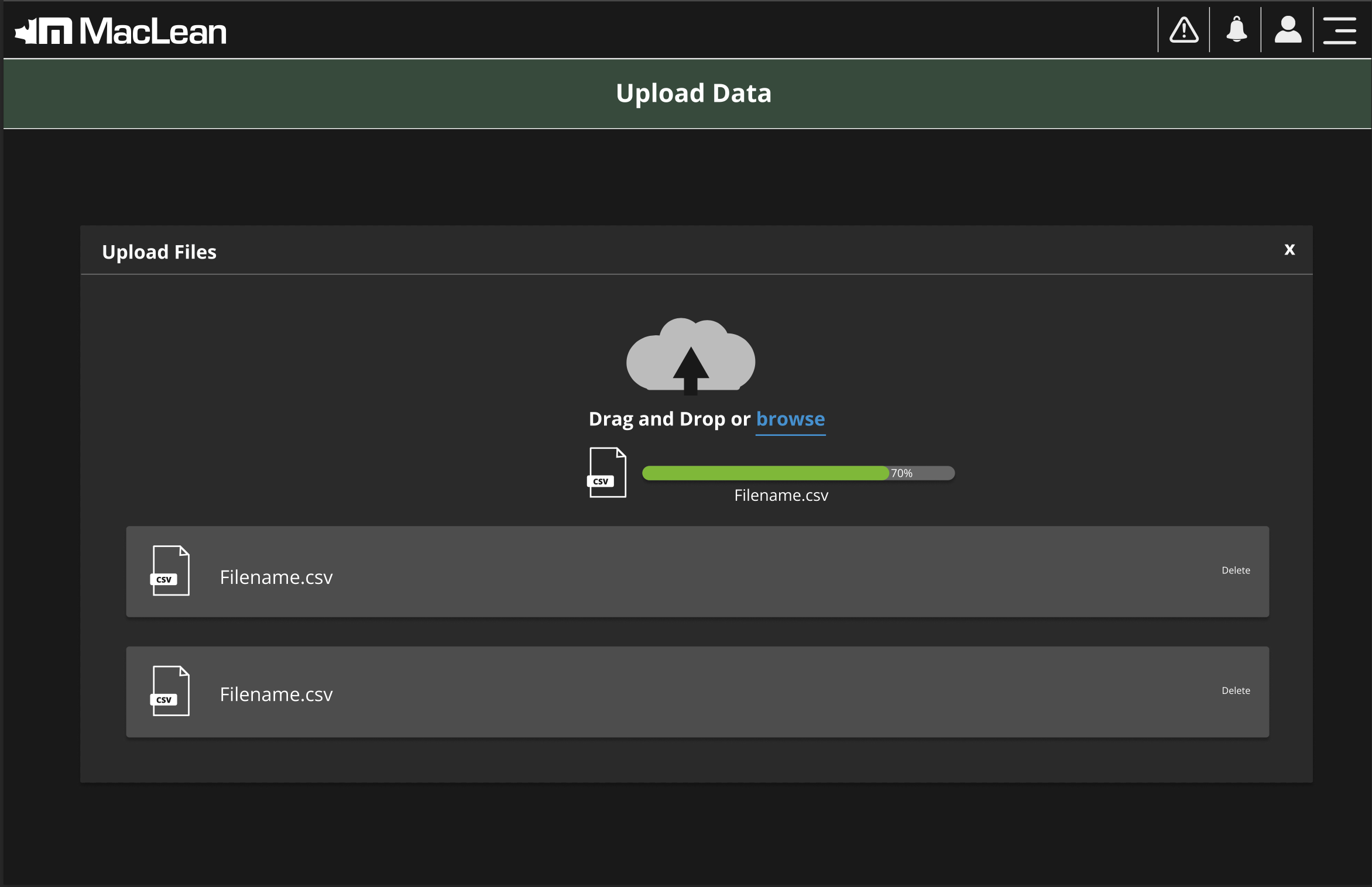

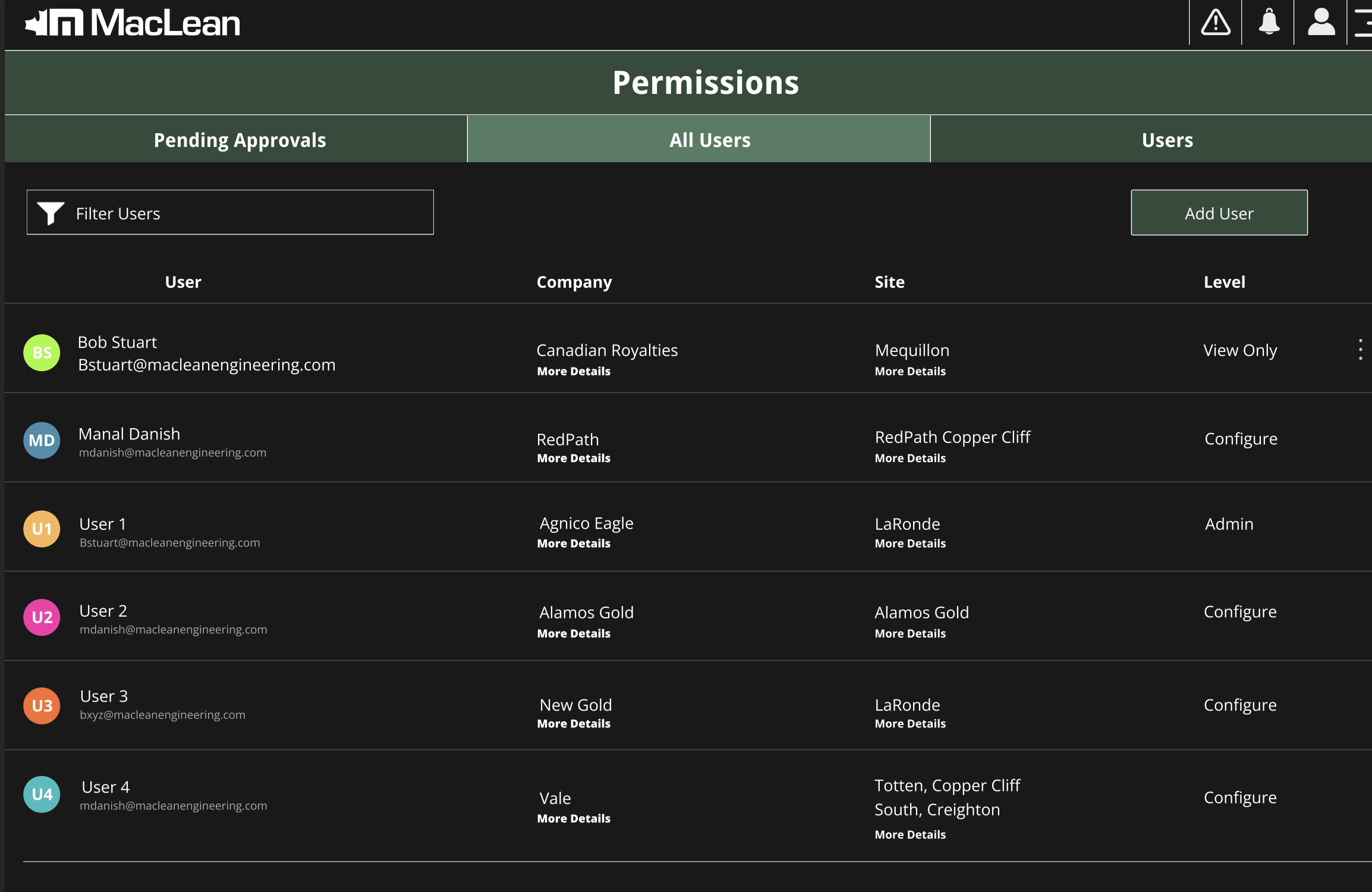

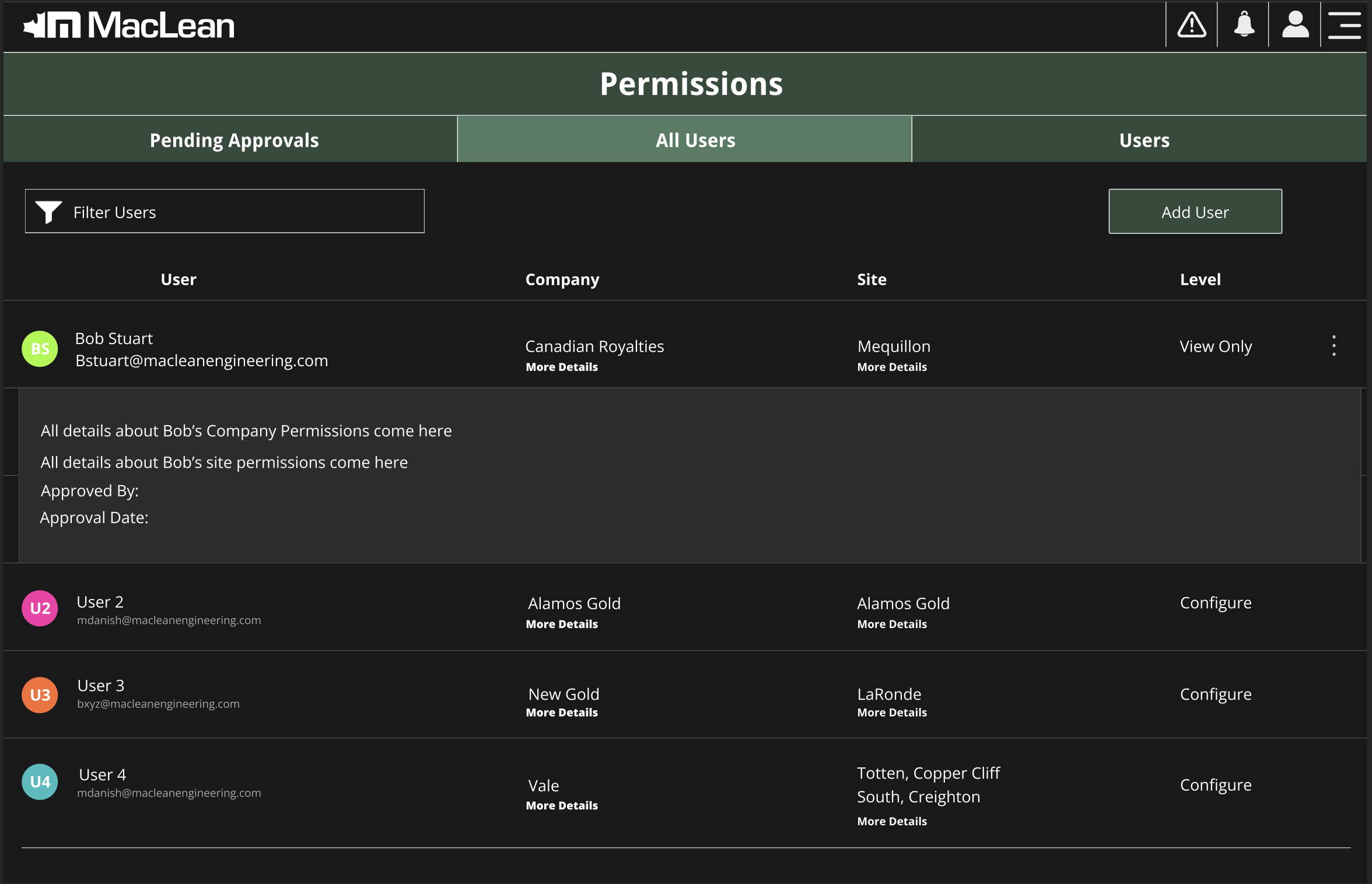

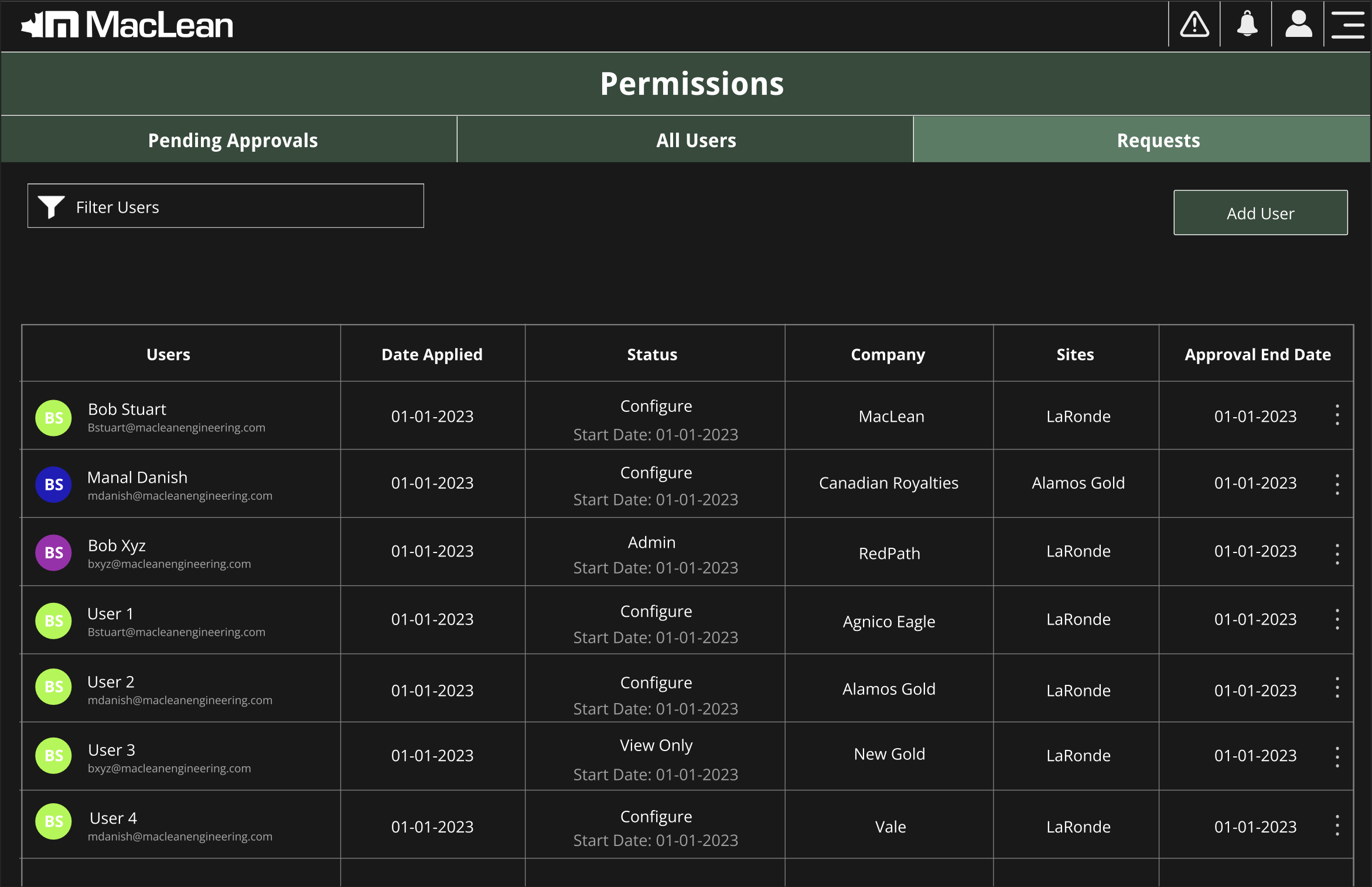

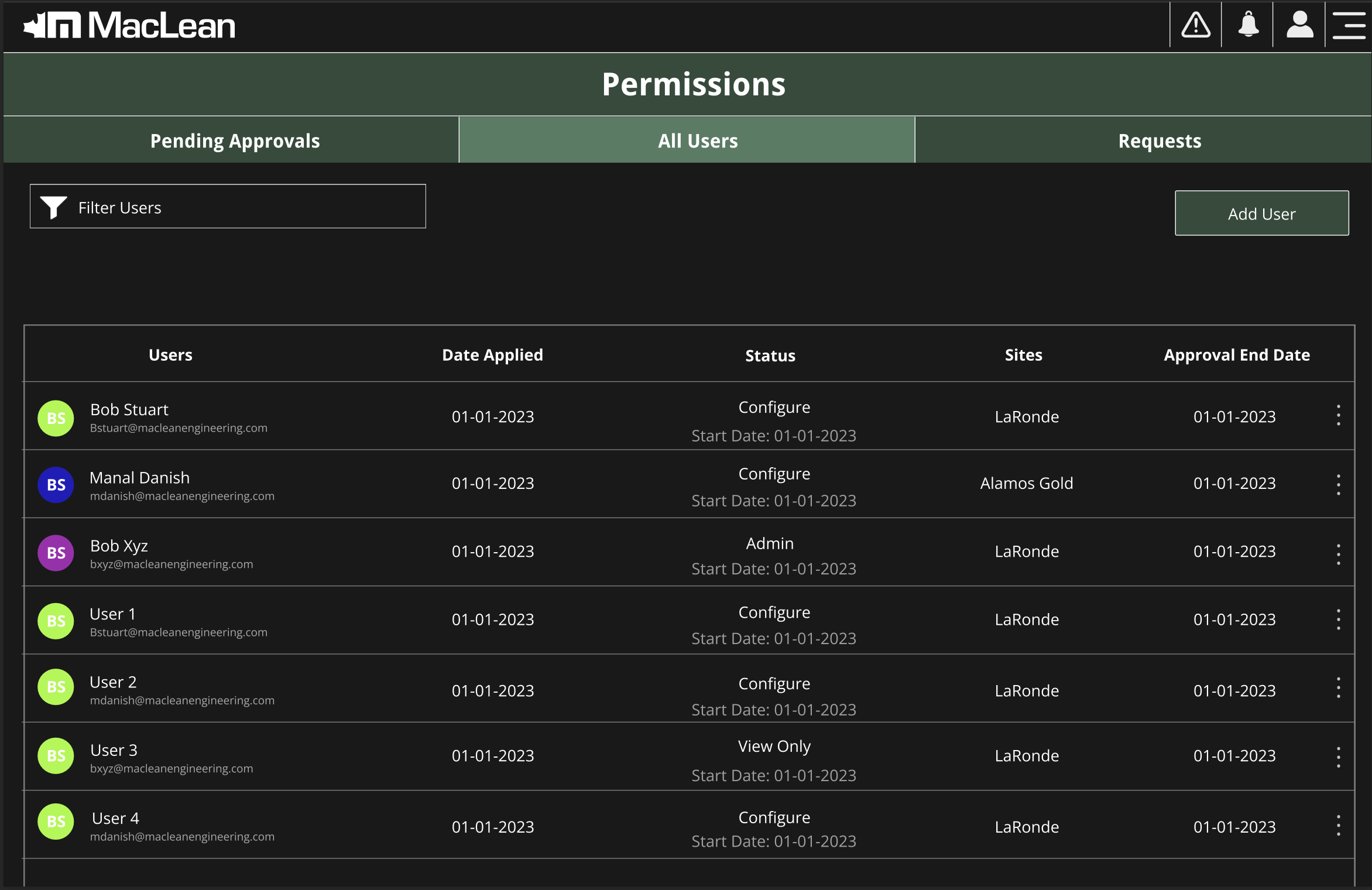

Above is the example of the dashboards I designed for the portal. It consists of all the details that our stakeholders needed.